W5FL

Veteran Member

- Joined

- Apr 7, 2000

- Messages

- 1,558

- Location

- Central Texas

- Tractor

- TYM T-1104/TX10 Loader Kubota M6800SD/LA1002 Loader Kubota RTV900

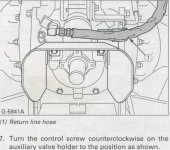

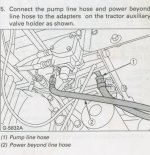

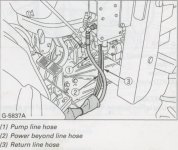

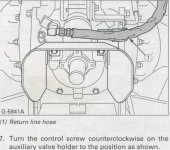

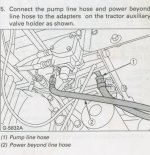

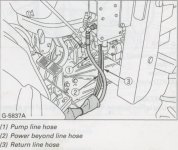

The dealer installed the loader a long time ago and it has always worked well, but when I was replacing all the loader hoses, I noticed that the diagrams in the LA1002 loader operators manual for the installation is different than the way my Kubota was delivered to me when new. First I connected the hoses up according to the manual, but the loader didn't work properly (wouldn't raise and actually went down). I had taken pictures and marked the cables, so I reversed the Pump line hose and the Power beyond line hose at the loader control as it was before removing the hoses, and that made it work ok! The Return line hose was never in question. Would anyone take a guess what reversing the hoses should have done? Should I put them back again or is it possible that the manual is wrong?

I also rigged up a gauge and measured the hydraulic pressure at the rear Auxiliary hydraulic connectors and the pressure looked ok, although a little low, but the rpm was also low. I was going to check the pressure at the loader, which comes from the Auxiliary block, but would you believe the quick connects are a different size (.75 diameter on the male) than the rear aux (.82 on the male which is standard for most implements). The Pressure Relief Valve works when a limit is hit for the aux and loader.

The loader, aux connector, and 3 point seems to work fine now, but sure like to know if I need to do anything else before it goes back in use running at PTO speed all day?

The connections are easy to differentiate as one has a 90 degree elbow (the Pump Line Hose) is the one nearest the front of the tractor and the other has a 45 degree elbow (the Pump Line Hose) is nearest the back end of the tractor.

The connections are also easy to see at the loader, as the return is a 1/2 inch hydraulic hose and the other two are 3/8 inch hydraulic hoses.

Return hose was ok.

I also rigged up a gauge and measured the hydraulic pressure at the rear Auxiliary hydraulic connectors and the pressure looked ok, although a little low, but the rpm was also low. I was going to check the pressure at the loader, which comes from the Auxiliary block, but would you believe the quick connects are a different size (.75 diameter on the male) than the rear aux (.82 on the male which is standard for most implements). The Pressure Relief Valve works when a limit is hit for the aux and loader.

The loader, aux connector, and 3 point seems to work fine now, but sure like to know if I need to do anything else before it goes back in use running at PTO speed all day?

The connections are easy to differentiate as one has a 90 degree elbow (the Pump Line Hose) is the one nearest the front of the tractor and the other has a 45 degree elbow (the Pump Line Hose) is nearest the back end of the tractor.

The connections are also easy to see at the loader, as the return is a 1/2 inch hydraulic hose and the other two are 3/8 inch hydraulic hoses.

Return hose was ok.