Hello TBN community, my tractor is a Kubota L2800 HST purchased new in '05. Presently only has about 450 hours on the meter.

Recently I lent it out and the notorious suction hose near the operator's right foot cracked. As a result all hydraulics were jerky/weird/questionable but they used it for the remainder of the day, adding fluid occasionally (they never fully understood what happened).

Anyway, I replaced the hose and re-filled with fluid. Everything is mostly ok but I noticed if you take the 3pt lever (at the operator's right hip) all the way up you can hear the pump whine like it's bypassing? or blowing off? When the pump sounds like this the FEL is also slow to move in certain directions.

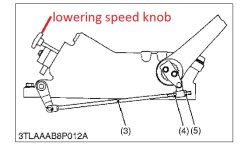

I was able to temporarily remedy the pump noise when the 3pt control is all the way up by simply putting a 1/4"-20 bolt and nut in the slot for the control lever - you only need to limit the uptravel of the lever by literally a 1/4" or less to make the noise go away. However the bigger annoyance is that the 3pt is VERY slow to drop now, which is annoying if you're doing repeated blade work in my case.

So, does anyone have any idea why I can't max the travel on the lever for the blade (er 3pt) to go UP without getting noise (bypass?) and why the 3pt is so slow to fall now?

I'm mechanically inclined but not great with hydraulics (obviously), so any guidance would be much appreciated!

Recently I lent it out and the notorious suction hose near the operator's right foot cracked. As a result all hydraulics were jerky/weird/questionable but they used it for the remainder of the day, adding fluid occasionally (they never fully understood what happened).

Anyway, I replaced the hose and re-filled with fluid. Everything is mostly ok but I noticed if you take the 3pt lever (at the operator's right hip) all the way up you can hear the pump whine like it's bypassing? or blowing off? When the pump sounds like this the FEL is also slow to move in certain directions.

I was able to temporarily remedy the pump noise when the 3pt control is all the way up by simply putting a 1/4"-20 bolt and nut in the slot for the control lever - you only need to limit the uptravel of the lever by literally a 1/4" or less to make the noise go away. However the bigger annoyance is that the 3pt is VERY slow to drop now, which is annoying if you're doing repeated blade work in my case.

So, does anyone have any idea why I can't max the travel on the lever for the blade (er 3pt) to go UP without getting noise (bypass?) and why the 3pt is so slow to fall now?

I'm mechanically inclined but not great with hydraulics (obviously), so any guidance would be much appreciated!