I'm trying to get the chain sprocket out of the tine shaft on a 30" JD mechanical tiller. The sprocket and spindle will spin on the tine shaft and slightly move out but will not pull further than 1/4 inch. I don't see a way to get in back of the sprocket to either pull it or push it out. Anyone ever do anything similar? Am I overlooking something obvious?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

John Deere 30 inch mechanical tiller disassembly problem

- Thread starter Al_W

- Start date

- Views: 5731

-

- Tags

- john deere tiller

More options

Who Replied?

/ John Deere 30 inch mechanical tiller disassembly problem

#1

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 3,037

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

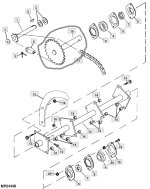

From your description and pictures, I would say that the bearing is stuck on the shaft. Did you unscrew the set collar, #7, on the bearing?

There is no longer a set screw on the collar and it is still stuck on the shaft. The bearing and race are mostly broken off anyway and the problem is the shaft of the chain sprocket that goes into the tiller shaft will not come out. The set collar would only keep the bearing in place and not the chain sprocket from being removed. I'm still working on it.From your description and pictures, I would say that the bearing is stuck on the shaft. Did you unscrew the set collar, #7, on the bearing?

oldnslo

Super Member

When shaft stops moving does it still turn freely? Just curious if over the years some crud has built up inside the tiller tine tube or if tube is slightly bent from use.

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 3,037

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

I'm missing something, but when you removed the setscrew, did you unscrew the collar from what's left of the bearing's inner race? The collar bites into the shaft to hold the bearing.There is no longer a set screw on the collar and it is still stuck on the shaft. The bearing and race are mostly broken off anyway and the problem is the shaft of the chain sprocket that goes into the tiller shaft will not come out. The set collar would only keep the bearing in place and not the chain sprocket from being removed. I'm still working on it.

The collar is still on the sprocket shaft but there is so little of the bearing left that with the flange bolts removed none of that--not the collar or the bearing--would keep that shaft from being removed IF it would only move freely. Anything left that is still on the sprocket shaft easily fits through the hole of the tiller side body.I'm missing something, but when you removed the setscrew, did you unscrew the collar from what's left of the bearing's inner race? The collar bites into the shaft to hold the bearing.

When shaft stops moving does it still turn freely? Just curious if over the years some crud has built up inside the tiller tine tube or if tube is slightly bent from use.

When I pull it out that little bit and it won't go further it is stuck at that point and will not turn freely. I'm at the point where I am almost ready to give up on it. I'd like to put a bomb under it and blow it up. Getting really frustrated because I have other things to do and can't spend all of my spare time with this.

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 3,037

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

Okay, so I think then that the holes that the retaining bolts go through a galled the shaft? If so, take a drill larger than the hole and use it to clean up the raised area of the shaft. To pull the shaft, fashion some wedges out of wood or stacks of metal behind the sprocket to help pry the shaft out.

I finally got it removed! I don't see anything obvious on either the inside of the tiller tine shaft or the sprocket rod that I finally got to come off. I had to remove some tines and get the bearing housing off on the other side of the tiller shaft in order to be able to twist, pull, wedge and cuss the sprocket off but it finally saw things my way. I'm uncertain about several things though. The sprocket still has the locking collar mounted to it and it is holding what I assume are the remnants of the ball bearing assembly. I shouldn't have too much trouble getting the collar off but the rest of what is left on the shaft--is all of it something to be removed or is any part of it something that belongs on that sprocket rod? I think it all has to go. I had hoped that John Deere had an actual photo of the sprocket but the only photo anyone found is completely bogus and might be some figment of ai's imagination. The pictorial sketch isn't much help either. Also--do I try to lightly sand the sprocket rod? How about the inside of the tine shaft? And when it comes to installing the bearings can I use a socket that would fit on the inner race and push it onto the shaft or lightly force it with a hammer? Is there some sort of tool I should be using to install the bearings safely onto the shaft? Even though the bearing on the opposite side seemed to be working it is not totally quiet so I'm going to replace that one as well while I have the opportunity. Then there is one more point bothering me--the grease that used to be under the chain cover and on the chain. The grease I removed was not anything resembling grease. It was dry and almost powdery. Has anyone ever seen that?

Attachments

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 3,037

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

The locking collar and the inner race of the bearing are still there as you suspect. A cutting torch will take those both off easily, but if you don't have one, a propane, preferably a MAP gas torch can be used to heat both pieces to a orange, red color, then cooled to loosen them up to beat off with a hammer.

Sand the shaft to remove burrs. A socket or pipe of the diameter of the inside race is proper to tap the new bearings on to the shaft. Yes, replace both bearings. There appears to by a snap ring or something beyond the bearing race. The book doesn't show anything AND it doesn't show a seal. There should be a seal in the case to keep the grease in and dirt out. I don't see one, so the tolerance between the shaft and housing should be very close and no wear at this point.

The "dust" in the chaincase is not a good thing and indicates that the grease leaked out. At this point, clean the case, chain and sprockets thoroughly then use corn head grease, such as Tractor Supply Super S #00 Cotton Picker Spindle Grease

Sand the shaft to remove burrs. A socket or pipe of the diameter of the inside race is proper to tap the new bearings on to the shaft. Yes, replace both bearings. There appears to by a snap ring or something beyond the bearing race. The book doesn't show anything AND it doesn't show a seal. There should be a seal in the case to keep the grease in and dirt out. I don't see one, so the tolerance between the shaft and housing should be very close and no wear at this point.

The "dust" in the chaincase is not a good thing and indicates that the grease leaked out. At this point, clean the case, chain and sprockets thoroughly then use corn head grease, such as Tractor Supply Super S #00 Cotton Picker Spindle Grease

Last edited:

I opted to use a dremel cutting wheel and chisel to get the locking collar off. Once that was removed I found that the inner race moved freely around but would not move freely off the sprocket shaft. Looking at the shaft closer I wonder if it is just a light rust coating that is stopping it? Can I use naval jelly on that shaft or will that cause a problem with the steel on the shaft one day? Also there was an interesting "ridge" visible along the shaft when I removed the collar. I wonder if that was made into the shaft or if the setscrew of the collar shifting on it would have caused that ridge? It looks really too uniform for that to be the case. What can I use to smooth out the shaft evenly? You suggested sandpaper but I don't I want it smooth when finished or will that not matter? I may cut the "good" bearing off of the other side but I might try a bearing puller first--looks like I can pick one up for under $50. As for a seal--the chain and inside case will be repacked with grease AND a sealant used on the edge of the case when I close it back up. I would think that grease will enter between the spindle shaft and bearing but that looks to be by design. Since there is a dirt cap (item #6 on the drawing) I suppose that unless the dirt cap gets compromised--which is what happened to me (it rusted at one corner and allowed dirt and moisture in) it will work. Thank-you for your suggestions. This sort of thing is not what I am in any way familiar with. Electronics troubleshooting and repair was my life until I retired in 2021.The locking collar and the inner race of the bearing are still there as you suspect. A cutting torch will take those both off easily, but if you don't have one, a propane, preferably a MAP gas torch can be used to heat both pieces to a orange, red color, then cooled to loosen them up to beat off with a hammer.

Sand the shaft to remove burrs. A socket or pipe of the diameter of the inside race is proper to tap the new bearings on to the shaft. Yes, replace both bearings. There appears to by a snap ring or something beyond the bearing race. The book doesn't show anything AND it doesn't show a seal. There should be a seal in the case to keep the grease in and dirt out. I don't see one, so the tolerance between the shaft and housing should be very close and no wear at this point.

The "dust" in the chaincase is not a good thing and indicates that the grease leaked out. At this point, clean the case, chain and sprockets thoroughly then use corn head grease, such as Tractor Supply Super S #00 Cotton Picker Spindle Grease

Attachments

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 3,037

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

Rough spots are what is stopping it and sanding the shaft would be fine. Smoothing it out is what you want. Any kind of lubricant would help in assembly and would not hurt anything longrun.

I didn't see the dirtcap. The tolerance between the inside of that and the ridge/ring that the bearing slides against should be very close.

I didn't see the dirtcap. The tolerance between the inside of that and the ridge/ring that the bearing slides against should be very close.

pmsmechanic

Elite Member

- Joined

- Dec 6, 2013

- Messages

- 4,406

- Location

- Southern Alberta, Canada

- Tractor

- 4410 and F-935 John Deere, MF 245

Also when you tighten up the collars on the bearings during reassembly, they need to be tightened up in the opposite direction of shaft rotation. Otherwise they may loosen up over time and cause a worn area on the shaft.

pmsmechanic

Elite Member

- Joined

- Dec 6, 2013

- Messages

- 4,406

- Location

- Southern Alberta, Canada

- Tractor

- 4410 and F-935 John Deere, MF 245

I always sand the rust and foreign material off of shafts before reassembling. Usually I sand as much of the shaft as I can before taking the bearing off as it makes it easier to slide the bearing off.So would naval jelly be helpful or harmful before sanding? Would it be better to just sand it?

Ordinary sandpaper works ok but I buy emery cloth. Just tear a strip off as long as you want and wrap it around the shaft and polish to your hearts content. 100-200 grit works quite fine though a finer grit works ok too.

I have no experience with naval jelly but if it works I don't see the harm in it.

Last edited:

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 3,037

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

Navel jelly, petroleum jelly? Would be fine.

Or, use the grease you are going to use in the gearcase

Or, use the grease you are going to use in the gearcase

Last edited:

Any ideas for sanding the inside of the tiller shaft that got "ridged" from whatever burr was on the sprocket rod? I need to sand as far as about 4 or 5 inches into the metal tube. I'm looking at a sanding drum from Amazon--4 1/2 inches x 1". Not sure if it will work but it will only cost me about $25 to find out.I always sand the rust and foreign material off of shafts before reassembling. Usually I sand as much of the shaft as I can before taking the bearing off as it makes it easier to slide the bearing off.

Ordinary sandpaper works ok but I buy emery cloth. Just tear a strip off as long as you want and wrap it around the shaft and polish to your hearts content. 100-200 grit works quite fine though a finer grit works ok too.

I have no experience with naval jelly but if it works I don't see the harm in it.

I decided against using any naval jelly. I remember using it on metal furniture before painting and the metal acts sort of strangely afterwards--almost like it tends to rust even more. Phosphoric acid. I'm just sanding.Navel jelly, petroleum jelly? Would be fine.

Or, use the grease you are going to use in the gearcase

pmsmechanic

Elite Member

- Joined

- Dec 6, 2013

- Messages

- 4,406

- Location

- Southern Alberta, Canada

- Tractor

- 4410 and F-935 John Deere, MF 245

Do you have a die grinder? If not get one for the job. They can be either electric or air with air being cheaper as long as you have enough of a compressor to run one. An electric drill might work but it's quite slow compared to a die grinder.

I use a 1/4" rod and cut a slot in the one end long enough to slide the emery cloth into. Slide the emery in at about the half way point of the strip and wrap it around the rod several times. As the strip gets worn you can tear about an inch off so that new emery gets in on the action. This setup will polish the inside quite nicely.

Another tip is that there are different qualities of bearings. Better ones last longer. Your bearing supplier should be able to help out with that. Also if you don't want as much rust the next time around purchase some sort of "never seize" and coat everything you have sanded with it during reassembly. It's messy to use but makes redoing something later much easier.

I use a 1/4" rod and cut a slot in the one end long enough to slide the emery cloth into. Slide the emery in at about the half way point of the strip and wrap it around the rod several times. As the strip gets worn you can tear about an inch off so that new emery gets in on the action. This setup will polish the inside quite nicely.

Another tip is that there are different qualities of bearings. Better ones last longer. Your bearing supplier should be able to help out with that. Also if you don't want as much rust the next time around purchase some sort of "never seize" and coat everything you have sanded with it during reassembly. It's messy to use but makes redoing something later much easier.

ning

Elite Member

Naval jelly - phosphoric acid - leaves a thin layer of iron phosphate that'll actually protect the metal, and phosphoric acid is relatively weak and takes a long time to affect clean steel - but it really goes after rust. To be safe, rinse a part you've used naval jelly on well, and then rinse with some baking soda solution to make sure you've neutralized any remaining acid, and rinse one more time with clean water.

I don't want to talk about navel jelly though

I don't want to talk about navel jelly though

Here are some similar links:

- Replies

- 0

- Views

- 2K