ceriderf

New member

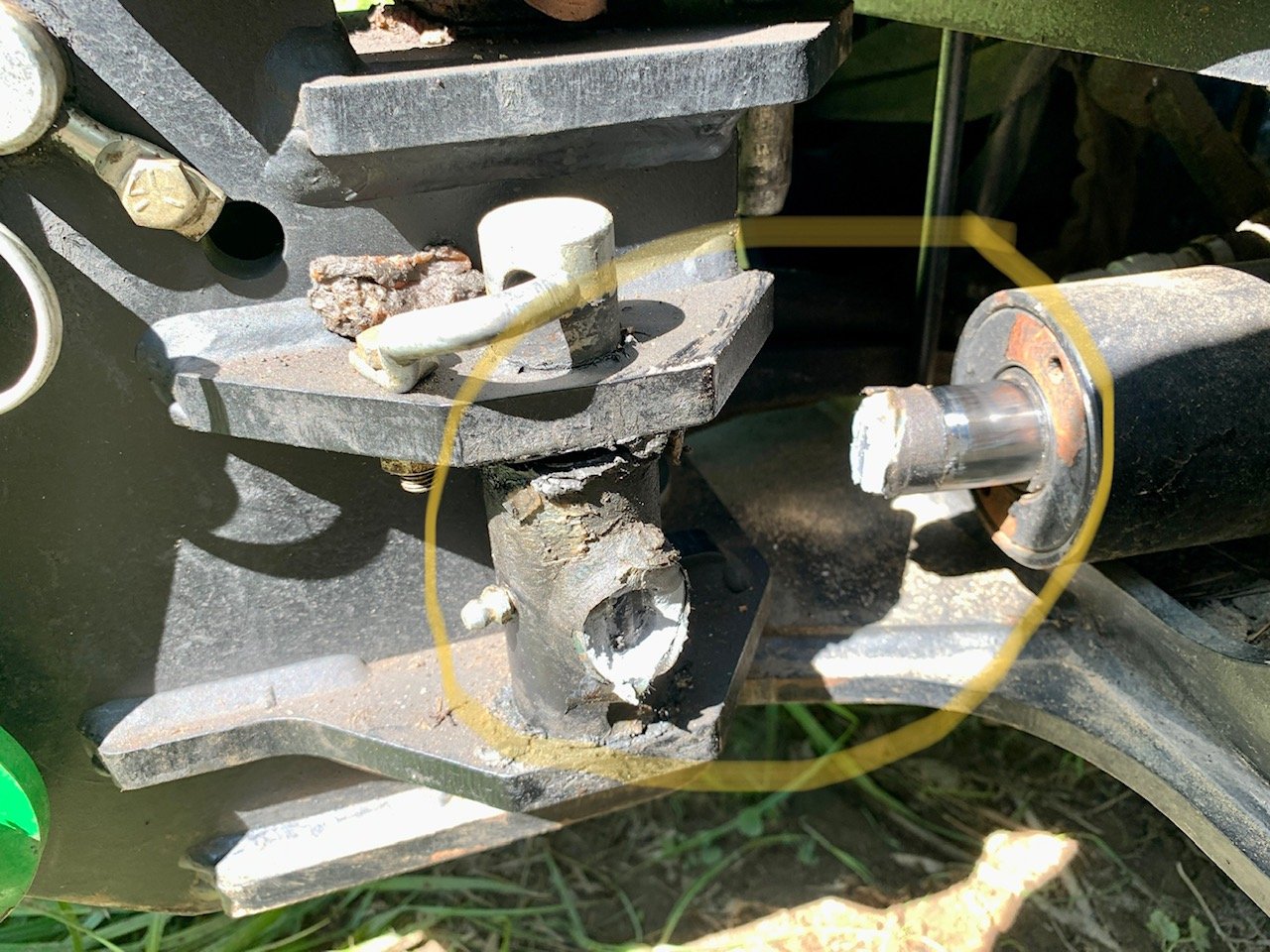

Battling with some roots from a large stump I pulled the bucket to the left and heard a loud snap! A friend saw the picture and thought the weld wasn't complete and offered to try and weld it back. The replacement part LVA14995 is $500.00 (SWING CYLINDER ST150490). Anybody have an idea how to take the cylinder rod out? I'm guessing just hammer the pin down (the retaining pin is already bent out of place) to pull the bushing out. The cylinder rod itself looks like there's a special tool to remove the guide? It has two holes in it and looks like there might be special wrench that fits it. Any ideas on how to get it off without that special wrench?

Thanks!

Thanks!