Steverino

Silver Member

Cause I try and I try and I try and I try! -

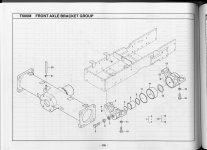

Try to get grease into the blasted fittings on the front axel bracket group. There are two fittings labeled 4 & 15 in the accompanying illustration that need to be greased. When I attempt to do so neither will accept any. When I unscrew the fittings there is grease present in the joint and I can easily push grease through the fittings while they are out. When reinstalled though nothing move in and the grease will eventually push out from the grease gun / fitting connection. I do not see any grease emanating from any of the machined surface that makes up the assembly. Any insight as to how to get this connection greased and where the overflow grease should be seen would be appreciated.

Try to get grease into the blasted fittings on the front axel bracket group. There are two fittings labeled 4 & 15 in the accompanying illustration that need to be greased. When I attempt to do so neither will accept any. When I unscrew the fittings there is grease present in the joint and I can easily push grease through the fittings while they are out. When reinstalled though nothing move in and the grease will eventually push out from the grease gun / fitting connection. I do not see any grease emanating from any of the machined surface that makes up the assembly. Any insight as to how to get this connection greased and where the overflow grease should be seen would be appreciated.