MinnesotaEric

Super Member

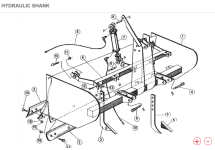

Travis, I thought you and Ted may be interested in this variant design by Modern Ag Products. Instead of rotating the scarifiers, Modern pulls them straight up. The scarifiers are pulled straight up. In the following two photos you can see how each scarifier is held in a captured slot.

BTW, don't make your scarifiers too strong as you want them to break before bending or breaking anything else in order to be a sacrificial part in order to save the box scraper frame as well as the three point on the tractor itself.

BTW, don't make your scarifiers too strong as you want them to break before bending or breaking anything else in order to be a sacrificial part in order to save the box scraper frame as well as the three point on the tractor itself.

Attachments

Last edited: