Schmeissermp38

New member

- Joined

- Feb 21, 2019

- Messages

- 7

- Location

- Margaret River, Western Australia

- Tractor

- Massey Ferguson 188, Caterpillar D8K

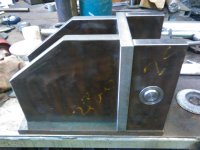

Hello to all, I just thought I would share my build of my yet unfinished block splitter. I decided to build one after sawing up a log which I thought was going to be a easy split, only to find it so hard that the hand splitter bounced off. So I thought that's it, I am going to build a hydraulic splitter. I found some plans on the internet and proceeded to modify them to what I wanted. The main tank is a piece of 250mm x 150mm x 9mm RHS which I managed to get cheap. The drawbar is 75mm x 75mm x 6 SHS. I have bolted the axle to the main tank with 3 sets of plates that are welded to the RHS. I made some plates up to hold the 75mm shs to the tank, they are bolted also. I then made up the pivot arrangement for the main I beam.

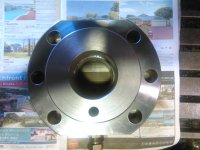

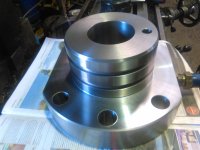

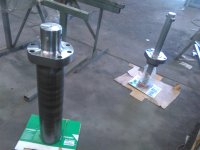

The stubb axles are inserted and welded into 50 x 50 x 6 shs, so they shouldn't bend. I then machined all the holes for the fittings I am going to put on the tank in the milling machine. I have put a large suction strainer on the inlet and a large diffuser on the outlet. All rated to over 120 litres per minute. Once all the fitting were put inside and tighted and sealed the ends were welded on as were the top plates and axle mounts. I trail assemble was made.

I was happy with the result and thought, we are well on the way. Little did I know how much more I had to do and what I had let myself for. lol.

Howard

The stubb axles are inserted and welded into 50 x 50 x 6 shs, so they shouldn't bend. I then machined all the holes for the fittings I am going to put on the tank in the milling machine. I have put a large suction strainer on the inlet and a large diffuser on the outlet. All rated to over 120 litres per minute. Once all the fitting were put inside and tighted and sealed the ends were welded on as were the top plates and axle mounts. I trail assemble was made.

I was happy with the result and thought, we are well on the way. Little did I know how much more I had to do and what I had let myself for. lol.

Howard