KubotaCrossing

Member

Am having Post Pounder envy ! It's only 26 hours driving time to get here

You might "rethink" the mechanism.

Use the hydraulic cylinder to raise the weight up to a mechanical latch.

When the cylinder retracts to it;s fullest, it releases the latch by way of a mechanical link.

The weight drops in free fall. Ready to be raised again up to the latched position.

If simple dumb steel works, there is no reason to pump oil ;-)

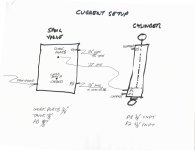

Have we determined where the restriction is yet? Spool valve? Hoses? Cylinder vent? (I assume we can eliminate back into tractor by using short big hose and a bucket? )

I think I would have made some type of clicker latch so the weight is falling free. Have the cylinder lift the weight up to point where it's then disengaged from the lift cradle/cylinder. Power return the cylinder to latch the weight in the cradle and the cycle repeats.