I've decided it is time upgrade from my old wooden forks that I've used for the past 15 years! (See attached picture of the old wooden one.) They've served me well but since they are stored outside, every year or two I have to replace cracked, worn or rotten bits of 2x in order to keep them in good working order. Additionally, as you can see from the picture, the wooden forks that I built use three 2x10s for the forks to provide some strength which means that I can't pick up a traditional pallet. Finally, I've always been a bit concerned about the real potential of a catastrophic failure that will of course occur at a most inappropriate time.

Anyway, I found a nice old set of 36" forks (for only $50) that, other than a bit of minor surface rust, are in pretty fair shape - the perfect size for my little JD 790. However, I'm going to have to make a carriage for the forks and then of course there is the minor little problem of converting my pin-on bucket to some sort of quick attach. I'm way too old to enjoy horsing attachments around to line up pins!

So, here's the priority list as I see it.

Wish me luck!

Anyway, I found a nice old set of 36" forks (for only $50) that, other than a bit of minor surface rust, are in pretty fair shape - the perfect size for my little JD 790. However, I'm going to have to make a carriage for the forks and then of course there is the minor little problem of converting my pin-on bucket to some sort of quick attach. I'm way too old to enjoy horsing attachments around to line up pins!

So, here's the priority list as I see it.

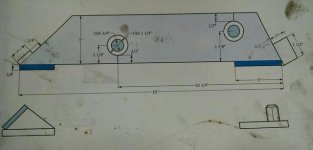

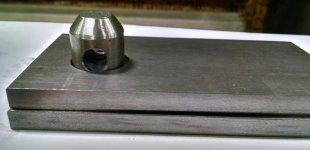

- Settle on a design for a quick attach that minimizes the loss of carrying capacity and that is doable with my skill set.

- Build the quick attach system and convert bucket over. And if that works, then

- Design and build a carriage for the forks using the same quick attach system.

Wish me luck!