JJ, 10 GPM is underrated for the 60hp tractor I'm looking at (17.9 GPM open center) and I could not find the schematic to learn if you are suggesting a different valving than what I diagrammed above. I see the sub plate has P, T, A and B, which is what I diagrammed, with the subplate porting one line on each side, threaded 9/16s (is that 3/8" hose then?) with 1/4" ports to the valve.

Question: should I be concerned about the 1/4" valving of the sub plate insofar as performance of the 3rd function?

To answer your question, yes, I plan to use a root grapple, a 72" combo bucket and an 8 or 8.5' snow plow on the loader. The snowplow will get crossover relief valve cranked up to 3,000 PSI (likely a Prince RV-4H with 1/2 fittings one since they come painted) and I'm wondering if I should include a cushion valve too so I kind of "mush" onto things?

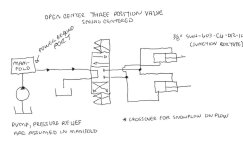

Valve wise, I was thinking of something like this

26 GPM Northman. However, you have me wondering what sub plate I need to use, given I need P, T, A and B. FWIW, I had thought

this sub plate would work which has A, B on one side and P and T on the bottom. What gives me pause though is the holes are in a different position going to the valve. Since I've never held any of these parts in hand, it makes me wonder if the valving will match?

I have Northman's subplate catalog here:

http://www.northmanfp.com/pdf/Subplate03.pdf