ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,499

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

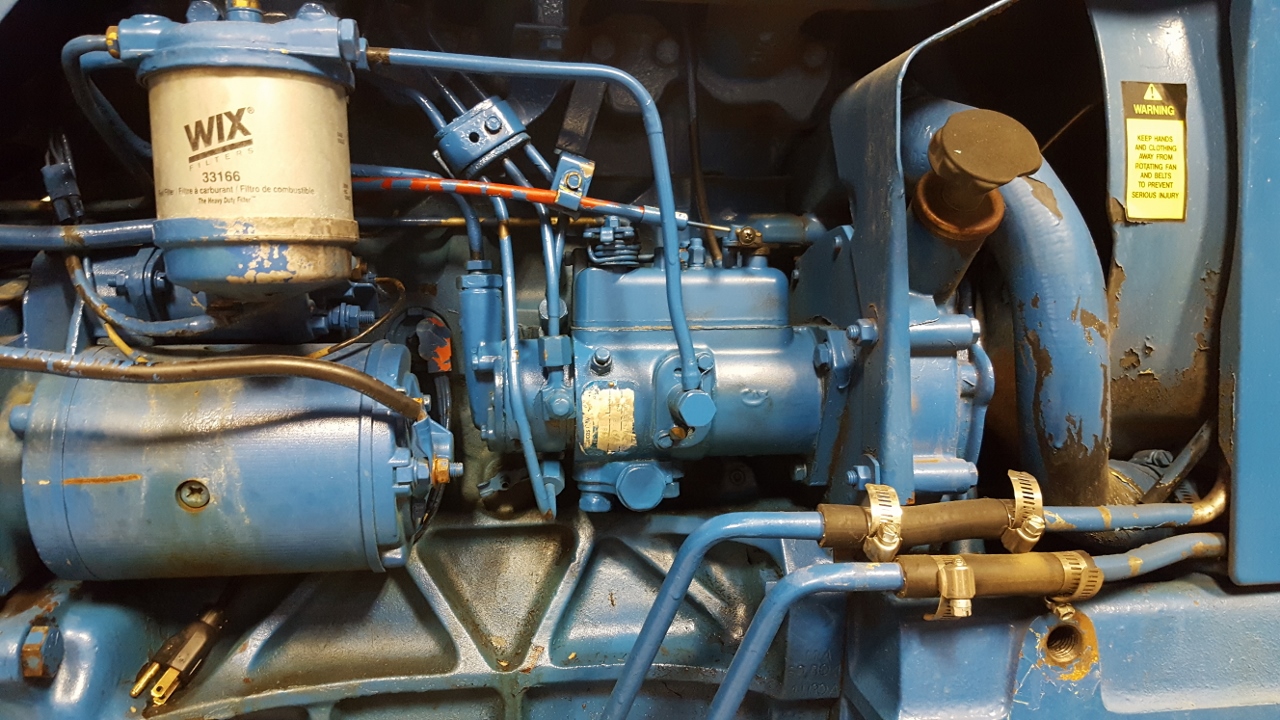

The Injector Pump on my 3910 has been seeping fuel since I bought the tractor two years ago. It got worse last Summer, to the point I would shut off the fuel when parked. Primarily was leaking from the O-ring that connects the two pump body parts. When the weather got cold it was so bad that fuel would pour from it when first cranked. So I hauled it to my warm shop for repair.

I talked to a good friend of mine that has a repair shop and primarily works on AG tractors of all types. Joe said "I never take a pump apart, I remove it and take it to a local shop for repairs". After I looked at the parts diagram I decided I wasn't going to take it apart either......

Removing the pump isn't extremely difficult. But attention needs to be paid!!!!! Particularly in the timing of the pump. Two things time the pump. The gear that drives it and the position of the pump. The three bolt holes that mount the pump to the engine are slotted. I carefully marked the pump housing and the engine case so I could get it back in the same spot.

Unhooking the various linkages and injector lines was pretty simple. Joe suggested removing the starter to make this process easier. Fortunately for me, I needed to replace my starter so it was coming off anyway. He also said it's easier to get the front cover off to expose the gear drive if the lower radiator hose is removed. The block drain petcock is right by the injector pump so I drained antifreeze until it was low enough to remove the upper end of the radiator hose without dumping.

I talked to a good friend of mine that has a repair shop and primarily works on AG tractors of all types. Joe said "I never take a pump apart, I remove it and take it to a local shop for repairs". After I looked at the parts diagram I decided I wasn't going to take it apart either......

Removing the pump isn't extremely difficult. But attention needs to be paid!!!!! Particularly in the timing of the pump. Two things time the pump. The gear that drives it and the position of the pump. The three bolt holes that mount the pump to the engine are slotted. I carefully marked the pump housing and the engine case so I could get it back in the same spot.

Unhooking the various linkages and injector lines was pretty simple. Joe suggested removing the starter to make this process easier. Fortunately for me, I needed to replace my starter so it was coming off anyway. He also said it's easier to get the front cover off to expose the gear drive if the lower radiator hose is removed. The block drain petcock is right by the injector pump so I drained antifreeze until it was low enough to remove the upper end of the radiator hose without dumping.