TractorBee

New member

- Joined

- Mar 5, 2021

- Messages

- 4

- Tractor

- IH 584, Massey F-40, JI Case 440

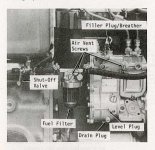

I am helping a friend of mine get a Ford 1700 he recently purchased up and running. Its a 2 cylinder diesel, the previous owners bypassed the fuel filter (it's missing the filter cup and element) and had the fuel line directly plugged into the injection pump. Some background, the tractor cranks and it has a new a starter, old one was bad.

So Far on the Fuel System:

I disconnected the hose from the pump to make sure I see flow from the tank and there was.

I then reconnected the hose to the pump and and disconnected the fuel lines between the pump and the injectors. I cranked it but there was only a trickle coming out of one port (the one closest to the driver, not sure if it is called #1 or #2).

Just to see, I also connected an electric pump to see if I could push fuel through the injection pump, but the results was the same, only a trickle coming out of the one port.

Where I Need Help and Advice:

My line of thinking is that the lines are plugged due to the bypass of the filter and gunk in the fuel tank (drained and clean yesterday, there was rust and debris), or some mechanical parts are gummed up due to age. I will take the side cover that is over the springs later today to see if there is movement (YouTube Video). However, my question is could I clean of the two port by pushing air into the pump with an air compressor to clean out any blockage, or is that likely to damage to the pump or would a can of compressed air would work better in this situation?

I haven't checked or changed out the oil in the injection pump (using the information on other post), but I plan on doing it later today. However, I wanted to get a better sense of what common issues maybe preventing the flow. Once I know the fuel is being delivered and pushing through the pump I will check the injectors, or have him replace both.

So Far on the Fuel System:

I disconnected the hose from the pump to make sure I see flow from the tank and there was.

I then reconnected the hose to the pump and and disconnected the fuel lines between the pump and the injectors. I cranked it but there was only a trickle coming out of one port (the one closest to the driver, not sure if it is called #1 or #2).

Just to see, I also connected an electric pump to see if I could push fuel through the injection pump, but the results was the same, only a trickle coming out of the one port.

Where I Need Help and Advice:

My line of thinking is that the lines are plugged due to the bypass of the filter and gunk in the fuel tank (drained and clean yesterday, there was rust and debris), or some mechanical parts are gummed up due to age. I will take the side cover that is over the springs later today to see if there is movement (YouTube Video). However, my question is could I clean of the two port by pushing air into the pump with an air compressor to clean out any blockage, or is that likely to damage to the pump or would a can of compressed air would work better in this situation?

I haven't checked or changed out the oil in the injection pump (using the information on other post), but I plan on doing it later today. However, I wanted to get a better sense of what common issues maybe preventing the flow. Once I know the fuel is being delivered and pushing through the pump I will check the injectors, or have him replace both.