You're going to find that your sliding supports that hold the trailer in the open position, are going to be a problem down the road. It's a great design idea, don't get me wrong, however the usual dirt, road salt, and rust are going to get into there, and gradually make it more difficult to slide those supports in and out, thus preventing you from folding and unfolding the trailer.

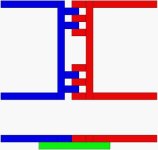

Anyway, a friend and I built a folding trailer. The front half and the tongue flipped over the back half of the trailer, which was a tandem axle design. I've attached a not-to-scale diagram illustrating how we hinged it, as well as how we kept it flat. The top section is a top view, and the bottom section is a side view. Sorry, my drawing skills are substandard.

The blue section is the front half of the trailer (actually, part of) and the red is the back half of the trailer. We used 2" sq x 0.125" tubing, and the bolts were 1" diameter. When we drilled the bolt holes through the square tubing, we drilled them oversized, then tapped in round tubing with a 1" ID, and welded that tubing to the holes drilled into the square tubing. Ground flat, of course. This tubing acted as a sleeve, so that the loads on the bolt didn't rest right at the head and the bottom of the thread, but rather spread more across the shank of the bolt. This is only important if you want to remove the bolts someday /forums/images/graemlins/grin.gif

The hinge design puts the bolts into double sheer, rather than single sheer, giving the bolts a chance to have some life expectancy.

The green piece in the bottom half of the image is a bolt on support, one per side, constructed also of 2" square tubing. I believe we used 0.250" wall tubing for that, and again, drilled holes and welded tubing through the bolt holes to act as a bushing. There were six bolts per side, three on the front section, three on the back section.

To fold the trailer up, it was fairly simple. We'd simply unbolt the green section and toss it onto the red section (which had the tandam axles), and fold the blue section (with the tongue) over the red section. Our design was not exactly ideal as we couldn't fold the front section flat over the rear section, but for my friend's purposes, this fit the bill. He was able to shove it into the back of the garge and have space in front of it, which is what he wanted.

I'm sure you could engineer our design a little further to get the front half to fold more flat upon the back half.

Also, it's proper trailer design to do a 60/40 split of the weight, meaning that the axle should be located 60 % of the way back from the front, and 40% forward from the rear. If it's a tandam axle trailer you're building, the centerpoint between the two axles should be at the 60% mark. THis way there is proper weight on the tongue (or gooseneck).

My friend hauled his 70 roadrunner to and from the track for a couple of years with this contraption, until he sold both as a set when his son was born and was instructed to buy diapers instead of car parts!

Good Luck.