dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,197

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

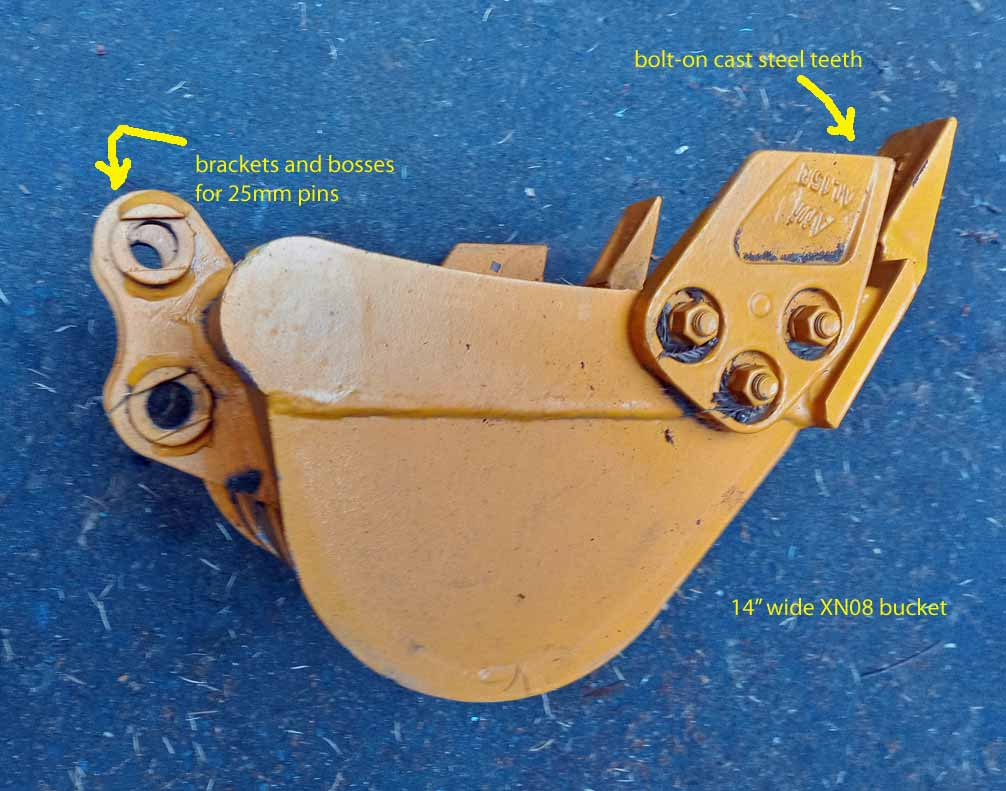

I recently imported a new mini-X from China, and it has been very useful. The buckets that came with it, however, leave a lot to be desired. They are too flimsy, too shallow, and use soft cast steel teeth.

This will be the 2nd bucket I have made from scratch, since I made one for my tow-behind mini-X, the CADDigger 728. Fabricating that bucket, back in the mid-90s, showed me how NOT to do it next time. BTW, the CADDigger designer (CADPLANS) is a TBN member. That bucket was 12" wide, and the carcass was 1/4" steel plate. Bending it into the curved shape necessary was tough, requiring lots of force and O/A torch heat.

First, let's look at the OEM 14" wide bucket and how it is made.

This will be the 2nd bucket I have made from scratch, since I made one for my tow-behind mini-X, the CADDigger 728. Fabricating that bucket, back in the mid-90s, showed me how NOT to do it next time. BTW, the CADDigger designer (CADPLANS) is a TBN member. That bucket was 12" wide, and the carcass was 1/4" steel plate. Bending it into the curved shape necessary was tough, requiring lots of force and O/A torch heat.

First, let's look at the OEM 14" wide bucket and how it is made.