So for an update, Hoye and I went back and forth several times to try to figure out what was going on. Hoye requested a used shift fork from their boneyard and compared it with a new one identical to the one that they sent me. They claimed that both are the same size and that the part number is the correct part number from the manual.

They said that it looks like part 60 from this manual:

TRANSMISSION_INTERNAL: Yanmar Tractor Parts could be worn from pictures that I sent, thus making the new part hard to fit correctly. I don't think this would result in what I was experiencing, but they suggested grinding down the top end of the shift fork to get it to fit. They suggested to be subtle on the grinding and check to fit often.

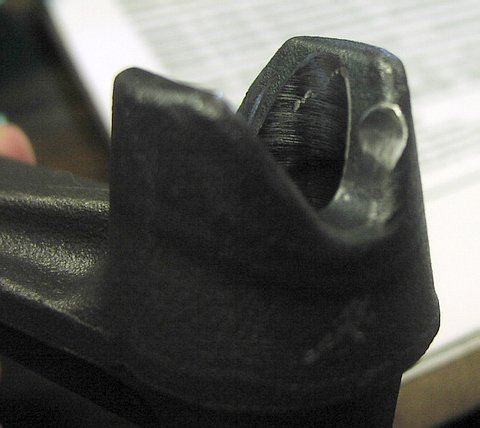

I went ahead and ground the topside of the shift fork until it slid into place, see picture below.

View attachment 751718

I used a flap disc and eventually got it ground enough. I used (2) #12 o-rings from Home Depot to replace the o rings on the diff lock pedal, measurements 5/8 in. I.D. x 13/16 in. O.D. x 3/32 in. wall thickness. These are ***-160 o-rings on Hoye's website. In order to get the compression spring that rides against the diff lock shift fork back into the transmission, I had to use a c-clamp to compress the spring. Once it was compressed, I was able to slide it off of the c clamp pad and against the shift fork. From there, it was a matter of installing the roll pins again and putting everything back together. Everything seemed to work ok, but it is yet to be tested. The diff lock shift fork was tight on the diff lock pedal, which has me a little worried.

www.tractorbynet.com