chad22

Veteran Member

Well today I headed off to our "me and my dad's" shop today to do some welding. I wanted to test my welding.

And I just so wanted to do some welding. I love melting metal together.

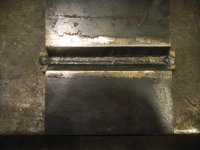

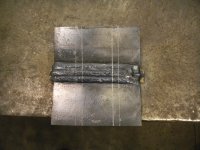

I had 2 pieces of scrap plate laying around that I cut off for something else. I decided to weld them up and then put them in our press to try and break the weld.

The weld held but the metal bent. Which is what I was hoping for. :drink:

After welding the plate I decided to cut a piece of pipe in half and then weld it back together. "First time I welded a pipe" I then put it in the press too and tried to break the weld into but it held and the jack on the press slid to the side and shot the pipe out backwards. Good thing I was standing clear.

It bent the pipe where the weld is but but didn't break the weld. :thumbsup:

I used 6011 1/8" rod and my Lincoln tombstone set at 115 amps.

After doing these tests I decided to make me a jack crank handle for my fifth wheel trailer jacks. I used the square tube it had with it and cut and welded it.

The plate isn't welded to the pipe it's just leaning against it for the pics.

The first pic shows the bent plate and the last pic shows the weld on the same bent plate in the first pic.

Chad

And I just so wanted to do some welding. I love melting metal together.

I had 2 pieces of scrap plate laying around that I cut off for something else. I decided to weld them up and then put them in our press to try and break the weld.

The weld held but the metal bent. Which is what I was hoping for. :drink:

After welding the plate I decided to cut a piece of pipe in half and then weld it back together. "First time I welded a pipe" I then put it in the press too and tried to break the weld into but it held and the jack on the press slid to the side and shot the pipe out backwards. Good thing I was standing clear.

It bent the pipe where the weld is but but didn't break the weld. :thumbsup:

I used 6011 1/8" rod and my Lincoln tombstone set at 115 amps.

After doing these tests I decided to make me a jack crank handle for my fifth wheel trailer jacks. I used the square tube it had with it and cut and welded it.

The plate isn't welded to the pipe it's just leaning against it for the pics.

The first pic shows the bent plate and the last pic shows the weld on the same bent plate in the first pic.

Chad

Last edited: