How do you know they didn't put any rebar at the front of your garage?

These are walls, not flat.

I have pictures and a movie of the inside of the forms before the pour. I used a metal detector after the pour. It's easy to determine what the metal detector is telling me.

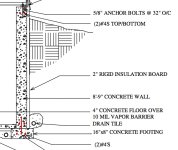

Do you put rebar in foundation walls? How much? Is it required by code?

Last edited: