Hi all,

I have a Kubota B7100HST-D 4WD with a mid-deck rotary mower RC70-71H. Three blades with the two-outer driven by a single belt and the central one off the gear box.

For the past 10 years it has operated without braking any blades. Recently the central blade is breaking regularly (every time is it used now) next to the cup washers. There is no visible damage to the broken blade.

What I have done to date is:

1. Replaced the seals, bearings and spindle holder.

2. Different brand of blades including a blade holder with standard mower blades. This would indicate that the blade is not hitting anything as a blade holder is half the size of a normal blade.

3. Visual inspection of deck shows no signs of damage

4. Raised the desk to reduce the chance of the blade hitting the ground.

I have stopped the tractor, checked and compared the temperature of the blade bolts. They are warm, but certainly not super-hot. Moments before the blade breaks there is a loud clanging sound and vibrations. Inspecting the half still remaining on the spindle, the bolt is tight and secure.

I am now out of ideas why this is happening and was wondering if anyone has come across the same problem or has any advice for troubleshooting this issue?

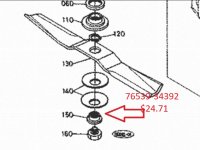

Is it possible I am tightening the bolt too much or the cup washers need replacing?

What purpose is the friction washer for?

Thanks in advance

Tate

I have a Kubota B7100HST-D 4WD with a mid-deck rotary mower RC70-71H. Three blades with the two-outer driven by a single belt and the central one off the gear box.

For the past 10 years it has operated without braking any blades. Recently the central blade is breaking regularly (every time is it used now) next to the cup washers. There is no visible damage to the broken blade.

What I have done to date is:

1. Replaced the seals, bearings and spindle holder.

2. Different brand of blades including a blade holder with standard mower blades. This would indicate that the blade is not hitting anything as a blade holder is half the size of a normal blade.

3. Visual inspection of deck shows no signs of damage

4. Raised the desk to reduce the chance of the blade hitting the ground.

I have stopped the tractor, checked and compared the temperature of the blade bolts. They are warm, but certainly not super-hot. Moments before the blade breaks there is a loud clanging sound and vibrations. Inspecting the half still remaining on the spindle, the bolt is tight and secure.

I am now out of ideas why this is happening and was wondering if anyone has come across the same problem or has any advice for troubleshooting this issue?

Is it possible I am tightening the bolt too much or the cup washers need replacing?

What purpose is the friction washer for?

Thanks in advance

Tate