I know this does not directly address the question asked but I'd like to supply some information and ask a question or two that may be generally relevant as it goes to the Cat 1/0 area of discussion.

When I bought my small patch of grass back in '08, I was still working FT and didn't take the time to think my early purchases through and instead listened to other 'well-meaning' friends in the neighborhood about what to buy. So off I went with a Kubota

M6040 and all the typical implements used in traditional farming. My reality ultimately set in and I realized everything I had was generally too large for what I wanted to do. My land is rolling hills, ponds, woodlot (SYP) and mostly what I do is occasional tree harvesting/transporting, Sawmilling, road maintenance, bush hogging, lite clearing, food plots and gardening. It's all done in relatively small patches of activity so Category 1 implements are plenty large for most all I do. I could likely get by with some of the lighter Cat 0 stuff too such as a rake. Ultimately, after owning the land for a while, I opted for a 35HP Ventrac rig with rear hydraulics and a 3 Pt Hitch - Power Rake, Brushcutter, Bucket + Rake and disc harrow for the rear (food plots). That works much much better for what I do. The rating on my 3 Pt Hitch is 750 lbs. Just today I was looking at a Kasco Vari-Maxx Seeder which I think would be great for my food plots but it weighs in at a whopping 960 lbs so can't be used with the Ventrac (with additional limitations listed in the next paragraph). It seems I run into issues like this a lot. Sometimes the rear attachments are just right and other times the Ventrac package just can't handle the lifting of the heavier units. It's not the HP, but the nature of the tractor's design and what is is 'mostly' designed to do.

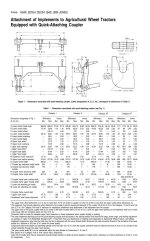

Somewhere here I think I ran across a comment about a Category 1 (Narrow) which sounds like what I may have on the Ventrac's 3PtH because though it is classified as a Cat 1 unit, the lift arms do not swing wide enough to get most of my Cat 1 attachments 'easily' mounted. I have also noted that the OAW of the lower lifting section of the implements vary from each other by as much as a couple of inches which makes the hook-up even more harrowing considering the limitations of my 3PtH. Currently, the only option I have is to reverse the direction of the lift arm pins to allow room to connect. Is it common to do this when one runs into these obstacles? I have no idea and cannot find anything on-line that discusses the reversing of lift arm pins and whether it's commonly done or if its a no-no.

1. Does anyone know what my problem is with the lift arm limitations of my 3PtH?

2. Can anyone direct me to the 'standards' of what the various Categories are dimensionally?

3. Any other input I consider valuable as I am a former city boy loving the country life and wishing to do it right.

Thanks