Farmwithjunk

Super Member

Ground speed isn't HELPING, but that mower should be able to take a bit of abuse.

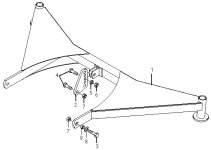

Something else jumps out at me. Is the "toggle" free to move? That's the flexable link just behind where the A-frame attaches to the quick hitch, and where the struts divide and continue to the rear of the mower. There should be EASY movement there. (see picture #3) Something looks peculiar in that picture. My 297 is still sitting at the dealer, waiting for delivery when they bring a new tractor that's on order. If I'm near there any time soon, I'll try to get a picture. Make certain that toggle is allowed to move freely to let the mower and tractor flex with irregular terrain.

Also, I don't see a problem with possibly using grade 8 bolts where you're snapping the grade 5's, OTHER than the fact that may make a more expensive component the weak link in the chain of events.

Raise the hitch, back the mower up where the tail wheels are over something a foot or so tall, then lower the hitch. Does that toggle flex and allow the front of the mower to continue down with ZERO resistance? If NOT, there's your problem.

On a Woods BB840 I owned, that toggle wouldn't allow ENOUGH flex. It moved freely, but ran out of travel in some situations. I cut a 12" section out of each of the top struts and replaced it with chain. That allowed substancially more freedom of movement. Proir to that, I was bending those struts every time I ran over a sizable irregularity.

Something else jumps out at me. Is the "toggle" free to move? That's the flexable link just behind where the A-frame attaches to the quick hitch, and where the struts divide and continue to the rear of the mower. There should be EASY movement there. (see picture #3) Something looks peculiar in that picture. My 297 is still sitting at the dealer, waiting for delivery when they bring a new tractor that's on order. If I'm near there any time soon, I'll try to get a picture. Make certain that toggle is allowed to move freely to let the mower and tractor flex with irregular terrain.

Also, I don't see a problem with possibly using grade 8 bolts where you're snapping the grade 5's, OTHER than the fact that may make a more expensive component the weak link in the chain of events.

Raise the hitch, back the mower up where the tail wheels are over something a foot or so tall, then lower the hitch. Does that toggle flex and allow the front of the mower to continue down with ZERO resistance? If NOT, there's your problem.

On a Woods BB840 I owned, that toggle wouldn't allow ENOUGH flex. It moved freely, but ran out of travel in some situations. I cut a 12" section out of each of the top struts and replaced it with chain. That allowed substancially more freedom of movement. Proir to that, I was bending those struts every time I ran over a sizable irregularity.