Over the last 4 weeks or so I've spent nearly every bit of spare time I had building my sunshade. 4 weeks worth of evenings and weekends later I've got it finished. I value the experience of putting it together, particularly from a beginner welder point of view, but if I'd known how long it would take, I'd not do it again unless I was being paid very well :laughing:

I'm very happy with the finished product, don't get me wrong, what bothers me is that I saved $100-200 and maybe not even that, but spent so much of my free time working on it. I did want something with a bit of fall protection to it. I don't think any of the flat top shades available offer much protection from falling objects and that is why I won't regret building it.

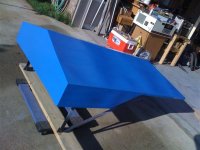

So here are the pictures, beginning to end with a few words where needed. Due to the amount of pics it is going to take several posts.

The first here are the beginning of the frame.

I'm very happy with the finished product, don't get me wrong, what bothers me is that I saved $100-200 and maybe not even that, but spent so much of my free time working on it. I did want something with a bit of fall protection to it. I don't think any of the flat top shades available offer much protection from falling objects and that is why I won't regret building it.

So here are the pictures, beginning to end with a few words where needed. Due to the amount of pics it is going to take several posts.

The first here are the beginning of the frame.

Last edited: