ptexer

Silver Member

- Joined

- Jan 26, 2011

- Messages

- 116

- Location

- Philippi WV

- Tractor

- farmall cub John Deere 310 Backhoe Loader Ventrac 4131

I have a farmall cub that I push snow with. It has a 5/8 - 14 inch bolt that attaches most of the pivoting pieces. I have been using a soft bolt from Lowes that break far from my shop and require repair in the cold and wind.

The bolt always breaks in the same place. I was considering taking the bolt and grinding 4 slots around the bolt at this place and filling with 7018. Do you think this would make it stronger.

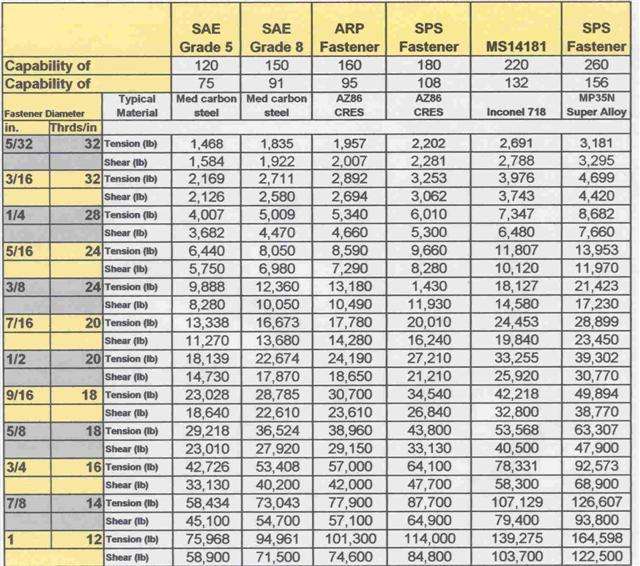

The other question is which is stronger stainless steel or grade 8 and does anyone know where to order bolts this size.

The bolt always breaks in the same place. I was considering taking the bolt and grinding 4 slots around the bolt at this place and filling with 7018. Do you think this would make it stronger.

The other question is which is stronger stainless steel or grade 8 and does anyone know where to order bolts this size.