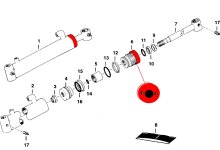

#6 is threaded into the cylinder body. Those 2 holes are for a spanner wrench but if it's stuck, a spanner won't help you. There may be a touch of loc-tite on the threads. Here is my suggestion. Put the base end back on the machine. Or better, use a good stable pipe vise or a way to lock it down. Heat the cylinder body by the cap with a propane torch. If you are very good with one, you could use oxy-acetylene but you don't want to over heat the cylinder body. Then take a big pipe wrench with a cheater pipe if need be and turn until it comes out. Sometimes, they are stuck, real stuck. It will come out.

Good Luck,

Andy