With the

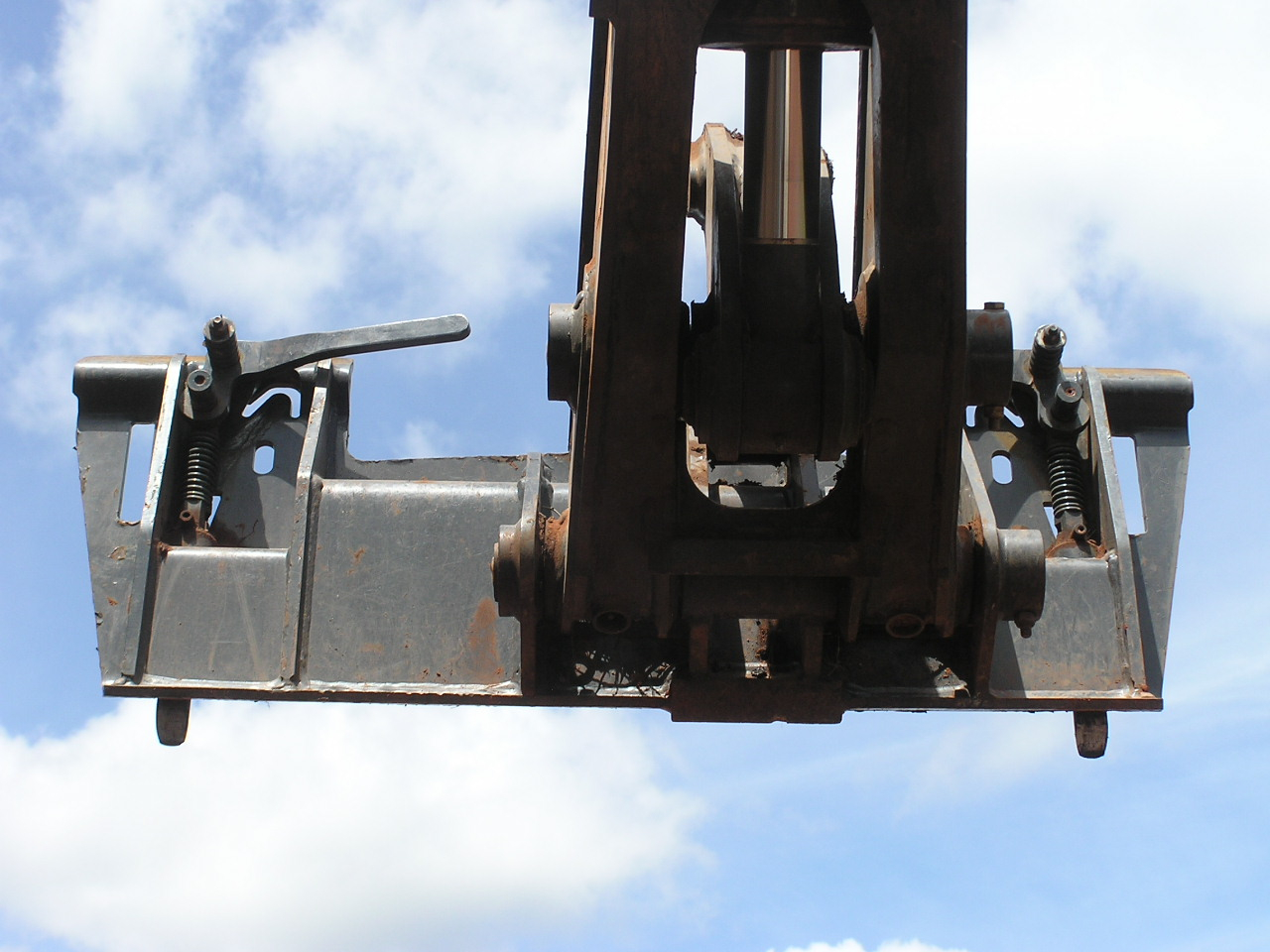

B26 the ssqa cross or torque tube is light gauge compared to rest of the loader. Simply not designed heavy enough to not twist without having an attachment locked in place. We mow with the ssqa attachments off for better clearance. The attachment pads have gotten out of time many times. Curling all the way back aligns the pads to engage ssqa locking pins from small miss alignment. Tree adjusts gross miss alignment. Was really concerned at first but after 7 years just a quirk of the machine. Have not seen any paint loss or fatigue damage. Tube is more of a spacer than torque keeper. Torque strength is from the attachment. If it ever fails the next tube will be heavier, square or rectangular tubing. Strong loader for this size tractor. Cutting and welding the OEM tube would be a lot of work for a temporary fix.

Of the many ssqa loaders I’ve had it is the only one to do this. Suspect many of the small loaders could have this condition. Haven’t seen this with the larger loaders but usually have an attachment on. Use Chain, tree or concrete floor best option. No big deal.