Gordon Gould

Super Member

- Joined

- Apr 1, 2007

- Messages

- 6,756

- Location

- NorthEastern, VT

- Tractor

- Kubota L3010DT, Kubota M5640SUD, Dresser TD7G Dozer

I don't have a welding bench. I make do with a 5' length of 3/8 plate 12" wide and a couple saw horses. Move it around, outdoors, garage, or basement like now. It gets old. I saw this thread and got inspired to build a 2' X 3' welding cart.

http://www.tractorbynet.com/forums/...-work-weld-table-post4019112.html#post4019112

I weld up little do-dads and repair stuff so it should be good for me.

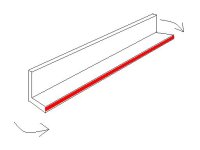

I welded up an upper and lower 2' X 3' frame. When I was done they were flat working off my table saw bench. I welded 4 legs in the corners of one frame. Braced them in a crude way while welding.

Now my question - when I finished welding the 4 legs the frame was racked so if I put it down like a 4 legged table one leg was off the floor 1/2". Understand I don't have a feel for what is or isn't a problem. My background is carpentry. The material is 1-1/2" X 3/16 angle. If I kneel on a short side and support my upper body on the other it takes very little pressure to straighten it out. If I clamp the other frame to the legs as if to weld it and let the structure free stand it becomes flat again. I plan on a 1/4" top and a 1/8" lower shelf with some belly bands.

I weld with a torch so expansion and contraction is a factor. Should I just go ahead and weld it up and hope for the best not having much to clamp it to other than a 12" plate. Or should I try to straighten the racked frame first. If I need to straighten how do I do that ?? heat or brute force??

Thank you.

http://www.tractorbynet.com/forums/...-work-weld-table-post4019112.html#post4019112

I weld up little do-dads and repair stuff so it should be good for me.

I welded up an upper and lower 2' X 3' frame. When I was done they were flat working off my table saw bench. I welded 4 legs in the corners of one frame. Braced them in a crude way while welding.

Now my question - when I finished welding the 4 legs the frame was racked so if I put it down like a 4 legged table one leg was off the floor 1/2". Understand I don't have a feel for what is or isn't a problem. My background is carpentry. The material is 1-1/2" X 3/16 angle. If I kneel on a short side and support my upper body on the other it takes very little pressure to straighten it out. If I clamp the other frame to the legs as if to weld it and let the structure free stand it becomes flat again. I plan on a 1/4" top and a 1/8" lower shelf with some belly bands.

I weld with a torch so expansion and contraction is a factor. Should I just go ahead and weld it up and hope for the best not having much to clamp it to other than a 12" plate. Or should I try to straighten the racked frame first. If I need to straighten how do I do that ?? heat or brute force??

Thank you.