sstouder

New member

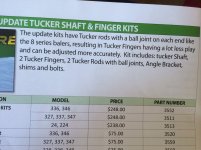

Hi. I know this subject has been talked about before a lot. I thought I'd see if there is any new thoughts on addressing the problem. I use an old, but well maintained, 336 baler. Bale grass hay. I get a share of banana-nose bales. Nothing too serious if you handle them correctly when picking them up and stacking them. I'm not really complaining as I've dealt with the problem for a long time. I try to keep a steady feed of hay into the baler and that seems to help if keep my windrows at the right density and don't let the hay get too dry. But I read somewhere that folks have used some newer designed 336 feeder fingers with more adjustment on them (my current fingers have three holes). Any thoughts on these or some other things I can do to help minimize the banana bales? Thanks much!