Sodo

Elite Member

- Joined

- Apr 21, 2012

- Messages

- 3,296

- Location

- Cascade Mtns of WA state

- Tractor

- Kubota B-series & Mini Excavator

Built this brush fork. It's 52 1/8" wide with 50" long tines. It's made of 1x2x.120 rectangular steel tubing. The bucket is 52 3/8", which is 1/4" wider than the brush fork. I believe 1/4" is the perfect clearance for something 52" wide, with about 1 foot of engagement (appx 4:1). It still gets bound up, but is easy to un-bind, I wouldn't want it any looser or any tighter.

The tines are a little too long, they can bend. My loader lifts 1,000 lbs and watching 50" tines flex with very heavy logs onboard, I'd say 40" might be more reasonable for a 1,000 lb FEL. But I can't bring myself to cut them (yet).

(yet).

Here you can see the angle-iron 'channels' that the fork slid into (original design months ago). As it is I rarely can design correctly the first time so I'm pretty much resolved to refinement by iteration. For me it's better to git'er done than wait for inspiration that may never come.

Today I removed the angle-irons and changed the mounting system to a couple sliding pins. There are many other ways, but I wanted a solution that was symmetrical and allows the fork to be flipped over someday as I'm not sure if I like the front angles in "safety mode" or "scoop mode". I will have to add a tab on the topside to invert the fork.

It was a bit of work (a 2 hour job that took 6 hours).

I did all this at my shop in the woods with a Miller MultiMatic200 MIG powered by two linked EU2000i honda generators (120v).

Added a tab below to engage the bucket cutting edge. It's 1/4" sheetmetal with a 3/16" doubler.

with a 3/16" doubler.

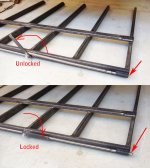

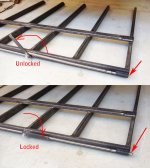

The 5/8" retractable pin is visible at the bucket corner.

The lever slides two pins in and out. The pins are 5/8" solid steel, and engage 5/8" holes in the corner of the bucket. No tools no loose parts required. This (I think) is essential, so you can quickly remove it and scoop stuff up with the bucket.

Ground a relief for grease, and drilled a hole to needle-grease the pin slider.

If any questions I'll try to answer them as best as I can.

The tines are a little too long, they can bend. My loader lifts 1,000 lbs and watching 50" tines flex with very heavy logs onboard, I'd say 40" might be more reasonable for a 1,000 lb FEL. But I can't bring myself to cut them

Here you can see the angle-iron 'channels' that the fork slid into (original design months ago). As it is I rarely can design correctly the first time so I'm pretty much resolved to refinement by iteration. For me it's better to git'er done than wait for inspiration that may never come.

Today I removed the angle-irons and changed the mounting system to a couple sliding pins. There are many other ways, but I wanted a solution that was symmetrical and allows the fork to be flipped over someday as I'm not sure if I like the front angles in "safety mode" or "scoop mode". I will have to add a tab on the topside to invert the fork.

It was a bit of work (a 2 hour job that took 6 hours).

I did all this at my shop in the woods with a Miller MultiMatic200 MIG powered by two linked EU2000i honda generators (120v).

Added a tab below to engage the bucket cutting edge. It's 1/4" sheetmetal

The 5/8" retractable pin is visible at the bucket corner.

The lever slides two pins in and out. The pins are 5/8" solid steel, and engage 5/8" holes in the corner of the bucket. No tools no loose parts required. This (I think) is essential, so you can quickly remove it and scoop stuff up with the bucket.

Ground a relief for grease, and drilled a hole to needle-grease the pin slider.

If any questions I'll try to answer them as best as I can.

Last edited: