chim

Elite Member

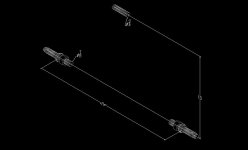

Re: 3pt hitch (Specs)

While I have no direct application for the info on the 3PH you've been posting on, I have enjoyed following it. The good drawings really add something to the discussion. Keep it up.....................chim

While I have no direct application for the info on the 3PH you've been posting on, I have enjoyed following it. The good drawings really add something to the discussion. Keep it up.....................chim