Steve_Miller

Veteran Member

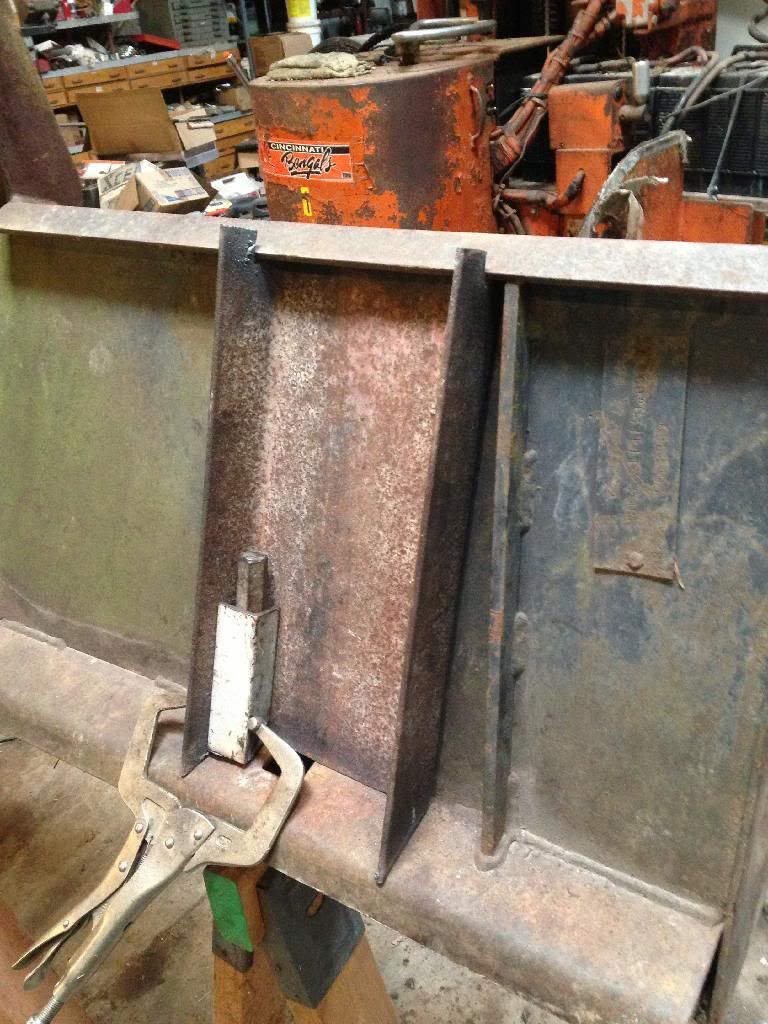

Well I put the post hole project on hold mainly because I haven't found an auger (cheap, I mean free) that I can use yet as a starting point. So I've started the quick attach for the 3PH. I am building from scratch and it may look similar to some other brand name hitch but I can assure you it is my own design. :mischievous: I used four by two tubing for the main uprights and two inch square tubing for the cross members. The rest of the parts and pieces are angle and flat bar. If anyone wants the dimensions I can post at a later date if you like. I built the main tubing part at work and used the wire feed welder, man what a treat compare to the Miller AC Thunderbolt. Some of my welds look professional and others look like a beginner. I have about 8-10 hours into it so far. I will post some more photos as I go along. Right now I am looking to perfect a simple pin setup other than the pivot type that usually come on the SSQA plates. I did a search several days ago and found a thread here somewhere where someone built a QA and used threaded rod and welded nuts on to screw the locking pins in place. Now I can find it for the life of me, I searched for an hour and couldn't find it, i was hoping someone could steer me to it. Any how more photos to come. You can criticize my welding if you like as I will have a chuckle over it, i know I do when I look at some of them, they usually look better after I grind them. Enjoy