IHDiesel73L

Silver Member

- Joined

- May 13, 2010

- Messages

- 167

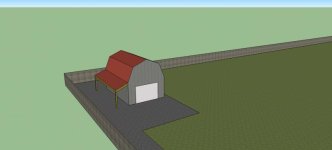

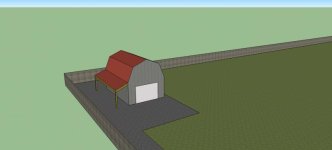

After a lot of back and forth about what to build and how to build it (and thanks to folks here who offered their knowledge) I finally pulled the trigger on the permits yesterday and got my approvals from zoning and construction in town. I'm doing a 16' x 24' Mini-barn which is probably the biggest I can go with without really encroaching on my yard space (1/4 acre lot). It will provide plenty of room for the OPE including the log splitter which is currently sitting outside under a tarp, as well as a boat, and lots of other stuff up in the two 8' x 16' storage lofts I'm building in. Finally, alongside I'll have 5 and 1/2 cords of covered and dry firewood storage via a lean-to. Here's what it's all going to look like:

I had initially planned on pole framing it and cladding the entire building in steel, but after I ran the numbers I found that it just doesn't make sense for a building this size from a cost perspective. For the walls, the cost of poles, girts, and steel exceeded the cost of stick framing and OSB composite siding every time no matter which way I sliced it. However, I still didn't want to pour a slab or a frost wall, so I searched around for solutions and found this:

http://bct.eco.umass.edu/publications/by-title/wooden-grade-beams/

In it, the author describes combining a concrete pier foundation with a treated wood "grade beam" or sill as the base of a building. The piers are poured and then the sills are bolted to the piers to form the perimeter of the building. The sill retains the gravel/stone dust floor on the inside and provides the attachment point for the exterior walls of the structure. I'll be pouring eight piers with 24" bases via "Bigfoot" concrete footings-cone shaped forms which fit conventional 8" form tubes. This way I can have a wide, solid base and use a fraction of the concrete in the process. Once the piers are poured and the 6 x 6 grade beams are bolted on, it will be pretty conventional. Stick framed walls 24" OC with two lofts on either end of the building tying the walls together.

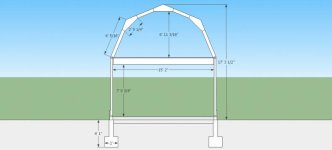

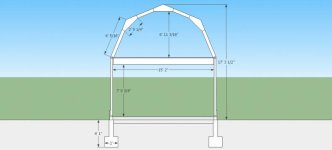

I'll be using a gambrel roof design in order to maximize storage space in the lofts, and also because I just like the look. The design was developed from looking at old USDA extension service plans and is a "braced rafter" type. In the old days they would brace the rafters with dimensional lumber to create an arch that would allow for a large hayloft with no center supports but still stand up to snow and wind loading. A lot of the designs I saw actually used 2 x 4s as rafters for spans as wide as 24' with rafter lengths of 10' I'll be upgrading to 2 x 6 rafters with 1/2" plywood gussets, glued and nailed. My rafters will only be 6' long and will be plenty strong. The roof will be clad in steel over purlins as it's still cheaper than sheathing in OSB, felt, and shingles-not to mention it's quicker and easier. I'm hoping to get started pouring concrete the weekend after Easter-more pictures to come.

I'll be upgrading to 2 x 6 rafters with 1/2" plywood gussets, glued and nailed. My rafters will only be 6' long and will be plenty strong. The roof will be clad in steel over purlins as it's still cheaper than sheathing in OSB, felt, and shingles-not to mention it's quicker and easier. I'm hoping to get started pouring concrete the weekend after Easter-more pictures to come.

I had initially planned on pole framing it and cladding the entire building in steel, but after I ran the numbers I found that it just doesn't make sense for a building this size from a cost perspective. For the walls, the cost of poles, girts, and steel exceeded the cost of stick framing and OSB composite siding every time no matter which way I sliced it. However, I still didn't want to pour a slab or a frost wall, so I searched around for solutions and found this:

http://bct.eco.umass.edu/publications/by-title/wooden-grade-beams/

In it, the author describes combining a concrete pier foundation with a treated wood "grade beam" or sill as the base of a building. The piers are poured and then the sills are bolted to the piers to form the perimeter of the building. The sill retains the gravel/stone dust floor on the inside and provides the attachment point for the exterior walls of the structure. I'll be pouring eight piers with 24" bases via "Bigfoot" concrete footings-cone shaped forms which fit conventional 8" form tubes. This way I can have a wide, solid base and use a fraction of the concrete in the process. Once the piers are poured and the 6 x 6 grade beams are bolted on, it will be pretty conventional. Stick framed walls 24" OC with two lofts on either end of the building tying the walls together.

I'll be using a gambrel roof design in order to maximize storage space in the lofts, and also because I just like the look. The design was developed from looking at old USDA extension service plans and is a "braced rafter" type. In the old days they would brace the rafters with dimensional lumber to create an arch that would allow for a large hayloft with no center supports but still stand up to snow and wind loading. A lot of the designs I saw actually used 2 x 4s as rafters for spans as wide as 24' with rafter lengths of 10'