Superduper

Platinum Member

- Joined

- Jul 18, 2006

- Messages

- 523

- Location

- Somewhere, over the rainbow.

- Tractor

- John Deere 3120, Kubota BX2350, Deere X740

OK, so years ago, I traded a wet grinder, a craftsman battery charger sized 200 welder (garage sale find) and a bosch combo hammer drill/demo chipper for this Miller welder. It's a dialarc 250. About to hit the big 5-0 and I figured I better finally learn how to do some welding and make a few projects before it's too late for me. I should say that this welder is nothing like I expected. The 200amp craftsman was maybe 50 pounds. Never used it but picked it up one day at a can't refuse price. The Miller is the weight of a small engine block. I think it's close to 400 pounds. Anyhow, when the trade offer came in, I asked a professional welder about his opinion and he told me that this model is a great machine and simply can't be compared with the cheapo 200 amp models like the craftsman I traded away. He said something like it welds like butter, whatever that means. I wasn't using the other stuff anyway so it seemed like maybe a good trade for both of us.

So had it all this time and it stares back at me every time I go into the garage but as I don't have a suitable plug, I never did get to use it. I am now thinking of finally installing the necessary outlet to play with this guy. So now the question..........

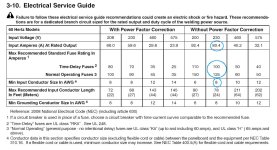

According to the owner's manual, 8-guage sizing is the minimum for the feeder wires to the outlet, which is fine with me. But the max fuse size of 125 amps? That would exceed my subpanel main breaker. It does say rated input current at rated output (miller dialarc 250) is 80.4 amps, which sounds like a lot based on what I read from other members here using 250amp machines. Apparently this machine can peform at 100% duty cycle at full 250amps. I am confident that I will probably never weld anything more than 3/8", maybe an occassional 1/2" tab or something. And as I have zero skills right now, would probably never weld at anything near the max duty cycle of this machine.

Would a 60 amp breaker be sufficient for what I will likely use this for?

So had it all this time and it stares back at me every time I go into the garage but as I don't have a suitable plug, I never did get to use it. I am now thinking of finally installing the necessary outlet to play with this guy. So now the question..........

According to the owner's manual, 8-guage sizing is the minimum for the feeder wires to the outlet, which is fine with me. But the max fuse size of 125 amps? That would exceed my subpanel main breaker. It does say rated input current at rated output (miller dialarc 250) is 80.4 amps, which sounds like a lot based on what I read from other members here using 250amp machines. Apparently this machine can peform at 100% duty cycle at full 250amps. I am confident that I will probably never weld anything more than 3/8", maybe an occassional 1/2" tab or something. And as I have zero skills right now, would probably never weld at anything near the max duty cycle of this machine.

Would a 60 amp breaker be sufficient for what I will likely use this for?