My 6" pulley arrived and I put it on the generator. When I run the tractor engine at "full" throttle, I get 61 Hz with the Kill-a-watt plugged into the generator head. Remember, I tached the engine at 3220 rpm under no load at "full" throttle. So my throttle cable could be adjusted to get the engine up to it's rated 3600 rpm at "full" throttle, but this happens to be perfect. Now if I plug in the 2Hp compressor, it starts up just fine, even if there's pressure in the compressor. I also tried welding while the air compressor was running, and that worked fine too. At this point, I have no need for any more power than this. So this is perfect, I have 3 different operating points to run this: 3" pulley with engine running at a fast idle for small loads up to ~1500 watts. 4" pulley with engine running at mid-throttle for loads ~2500(?) watts. 6" pulley with engine running at full throttle for the heaviest loads. I can't really say with any accuracy what those "heaviest" loads are in terms of watts, but if I can weld while the generator is running the 2 hp air compressor, that's all I need.

Now as for engines running at full throttle: That's what tractors are designed for. I grew up on a farm and we would plow a field, or run an implement for days and days, and it was typically at full throttle the whole time. The tractor engines seemed to run forever and never showed any sign of wear. So in the case of this 332 with a 3 cyl Yanmar diesel, sure it's not a farm implement, but the diesel will still run for 1000's of hours. Maybe there's more wear at full throttle vs fast idle, but who knows? I prefer half-throttle mostly because it's quieter, the engine sounds "better" and it uses less fuel.

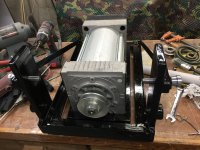

Now it's time to figure out a method for adding a bit of belt tension. Once that's done, a little bit of final cleanup and a few coats of paint.

Now as for engines running at full throttle: That's what tractors are designed for. I grew up on a farm and we would plow a field, or run an implement for days and days, and it was typically at full throttle the whole time. The tractor engines seemed to run forever and never showed any sign of wear. So in the case of this 332 with a 3 cyl Yanmar diesel, sure it's not a farm implement, but the diesel will still run for 1000's of hours. Maybe there's more wear at full throttle vs fast idle, but who knows? I prefer half-throttle mostly because it's quieter, the engine sounds "better" and it uses less fuel.

Now it's time to figure out a method for adding a bit of belt tension. Once that's done, a little bit of final cleanup and a few coats of paint.