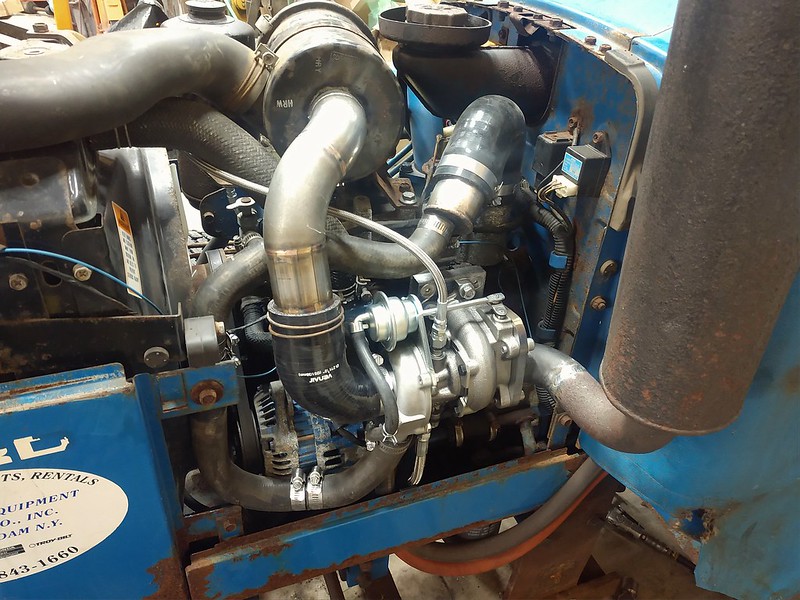

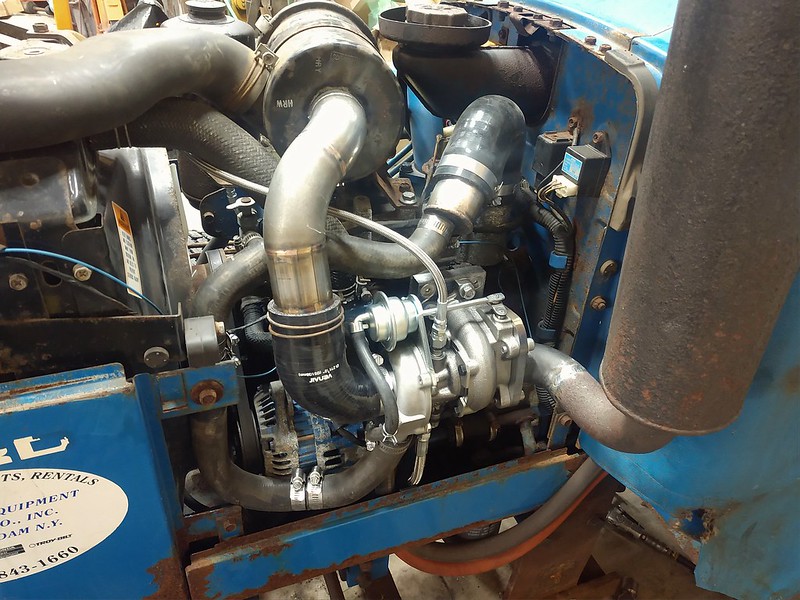

After the last snowstorm, it was very apparent my 1620 could use some more *** for blowing large drifts. For a total of $300, it's now turbocharged!

Disclaimer, diesel performance is what I do for a living. I fully understand the potential risks and methods for minimizing them.

Please don't judge the charge pipe, I needed something quick and easy as this whole job was done in under 7 hours. I'll eventually build a nice pipe out of 1" ss tubing and use a proper reducer to step up to intake manifold size. I'll post more pics tomorrow.

Disclaimer, diesel performance is what I do for a living. I fully understand the potential risks and methods for minimizing them.

Please don't judge the charge pipe, I needed something quick and easy as this whole job was done in under 7 hours. I'll eventually build a nice pipe out of 1" ss tubing and use a proper reducer to step up to intake manifold size. I'll post more pics tomorrow.