Garandman

Elite Member

- Joined

- Aug 3, 2014

- Messages

- 3,152

- Location

- Mount Sunapee NH / Dorchester, MA

- Tractor

- Kubota L3200 HST

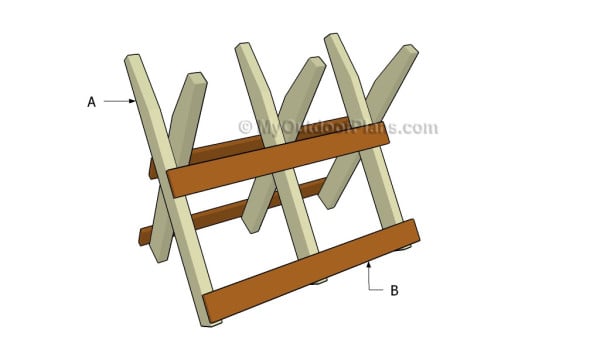

Yeah, I figured someone would say "LMGTFY" but as you can see from the results, most of them are for sale, not home made.Lots of ideas here: [GIS]

6x6 pressure treated is what I'm hearing.