Optiker

New member

I have two sickle mowers, a New Idea (NI) 30 that had sometime in its past been modified from pulled to 3-point, and a Massey Ferguson (MF) 31. I used the NI until the cast connection between the Pittman and the cutter bar broke, then bought the MF 31 to replace it. I was not experienced enough to realize that the MF was not in very good condition, but have since learned much. When it increasingly jammed, I learned a little and made some adjustments. It repeatedly broke the bolt that connected the cutter bar to the Dyna Balance arm. I finally gave up in frustration and payed my neighbor to mow (about 3 acres of grass hay, 3-4 cuttings/year) with his disk mower. Over a period of about three years, his mowing deteriorated and last fall, I told him that because it was leaving too much behind, I would try to get my sickle mower back in service. That gets me to my problem.

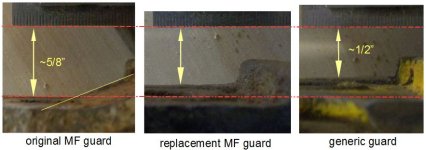

I've pulled the cutter bar of the MF 31, and removed all of the guards, hold down clips, wear plates and shims. I also removed the sections, which were all bad, with the exception of maybe two that were marginal. The ledger plates were all very bad. All of this probably explained the jamming, and probably also the broken bolts. Some of the guards had broken or bent "ears". There was a mix of guards including about half that appeared to be original MF, one that was a later MF, but not the correct one since it didn't match the beveled bottom front edge of the bar, and four other miscellaneous guards other than MF branded.

I pulled the guards from the NI mower, and found the ledger plates were a little worn, but not bad. That mower had cut pretty good. I also recalled that I had replaced most of the sections so that they were also in pretty good condition. Before pulling them to reinstall on the MF mower, I compared cutter bars and found that the NI bar was 2-3" longer than the MF bar, and by shortening it and re-drilling the holes for the connector bar, it looks like I can use it as-is (with already installed sections) in the MF mower.

So, the current plan is, use the NI guards on the MF bar, and modify and use the NI cutter bar in place of the MF cutter bar. I will also use wear plates, shims, and bolts from the NI as needed, and as they fit.

The questions... (1) Are the shims of different thickness so as to provide an adjustment, or are they for some other purpose? (2) How badly worn can the wear plates be and still be usable? (3) is there a web site where I can find a step-by-step overhaul/restore process description and/or a general checklist for things to check on a mower to make sure I've done all I can to make it work right? I don't really know anything about adjusting wear plates, though I understand the process of adjusting hold-down clips and ledger-section clearance. (4) Any comments on this approach?

As you might guess, at 3 acres of hay, this is really just a hobby, which makes dumping a lot of money into a new mower, or into a lot of new parts, not justifiable. I also don't know enough about tuning sickle mowers to know if even replacing all guards, sections, wear plates and shims with new, will result in a mower that does the job. The rest of the mower seems good, but I'm not experienced enough to know. That's also why I don't go looking for a replacement used mower - I don't care to spend a lot of money and have a mower that still needs this kind of work to get it working. I noticed on one of the sickle mower sites that I could buy a MF 31, claimed to be in excellent condition, for about $1700 - but it's in Kentucky and I'm in WA!

The rest of my equipment includes a MF35 tractor (Perkins diesel), an old Ford side-delivery rake, and a John Deere 214WS baler (wire). When I first got it, the baler would fail to tie about 1 out of 3 bales. Over the period of a couple of years, we got it to where it is now, and rarely fails to tie, with the exception of the first bale in an empty chute.

Any help would be greatly appreciated. FWIW...there is some time pressure since I've scheduled to mow my first cutting on 8 May. If no sickle mower, I guess I'll have to settle for my neighbor doing it and leaving probably 1/4 to 1/3 unmowed, that would otherwise be mowed with a sickle.

Thanks for any help you can provide!

Optiker

I've pulled the cutter bar of the MF 31, and removed all of the guards, hold down clips, wear plates and shims. I also removed the sections, which were all bad, with the exception of maybe two that were marginal. The ledger plates were all very bad. All of this probably explained the jamming, and probably also the broken bolts. Some of the guards had broken or bent "ears". There was a mix of guards including about half that appeared to be original MF, one that was a later MF, but not the correct one since it didn't match the beveled bottom front edge of the bar, and four other miscellaneous guards other than MF branded.

I pulled the guards from the NI mower, and found the ledger plates were a little worn, but not bad. That mower had cut pretty good. I also recalled that I had replaced most of the sections so that they were also in pretty good condition. Before pulling them to reinstall on the MF mower, I compared cutter bars and found that the NI bar was 2-3" longer than the MF bar, and by shortening it and re-drilling the holes for the connector bar, it looks like I can use it as-is (with already installed sections) in the MF mower.

So, the current plan is, use the NI guards on the MF bar, and modify and use the NI cutter bar in place of the MF cutter bar. I will also use wear plates, shims, and bolts from the NI as needed, and as they fit.

The questions... (1) Are the shims of different thickness so as to provide an adjustment, or are they for some other purpose? (2) How badly worn can the wear plates be and still be usable? (3) is there a web site where I can find a step-by-step overhaul/restore process description and/or a general checklist for things to check on a mower to make sure I've done all I can to make it work right? I don't really know anything about adjusting wear plates, though I understand the process of adjusting hold-down clips and ledger-section clearance. (4) Any comments on this approach?

As you might guess, at 3 acres of hay, this is really just a hobby, which makes dumping a lot of money into a new mower, or into a lot of new parts, not justifiable. I also don't know enough about tuning sickle mowers to know if even replacing all guards, sections, wear plates and shims with new, will result in a mower that does the job. The rest of the mower seems good, but I'm not experienced enough to know. That's also why I don't go looking for a replacement used mower - I don't care to spend a lot of money and have a mower that still needs this kind of work to get it working. I noticed on one of the sickle mower sites that I could buy a MF 31, claimed to be in excellent condition, for about $1700 - but it's in Kentucky and I'm in WA!

The rest of my equipment includes a MF35 tractor (Perkins diesel), an old Ford side-delivery rake, and a John Deere 214WS baler (wire). When I first got it, the baler would fail to tie about 1 out of 3 bales. Over the period of a couple of years, we got it to where it is now, and rarely fails to tie, with the exception of the first bale in an empty chute.

Any help would be greatly appreciated. FWIW...there is some time pressure since I've scheduled to mow my first cutting on 8 May. If no sickle mower, I guess I'll have to settle for my neighbor doing it and leaving probably 1/4 to 1/3 unmowed, that would otherwise be mowed with a sickle.

Thanks for any help you can provide!

Optiker