I'll post more pics of the land and views eventually.

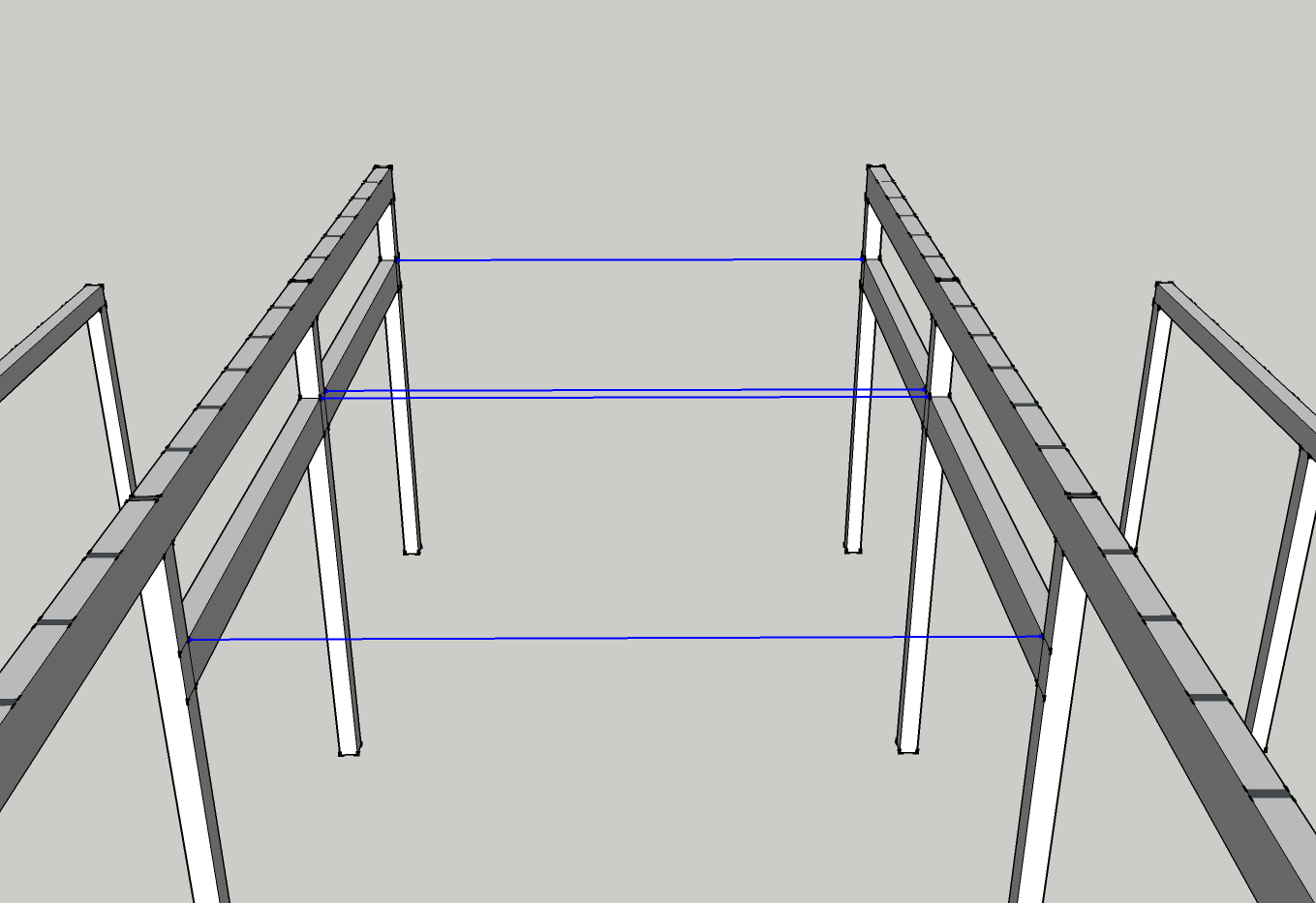

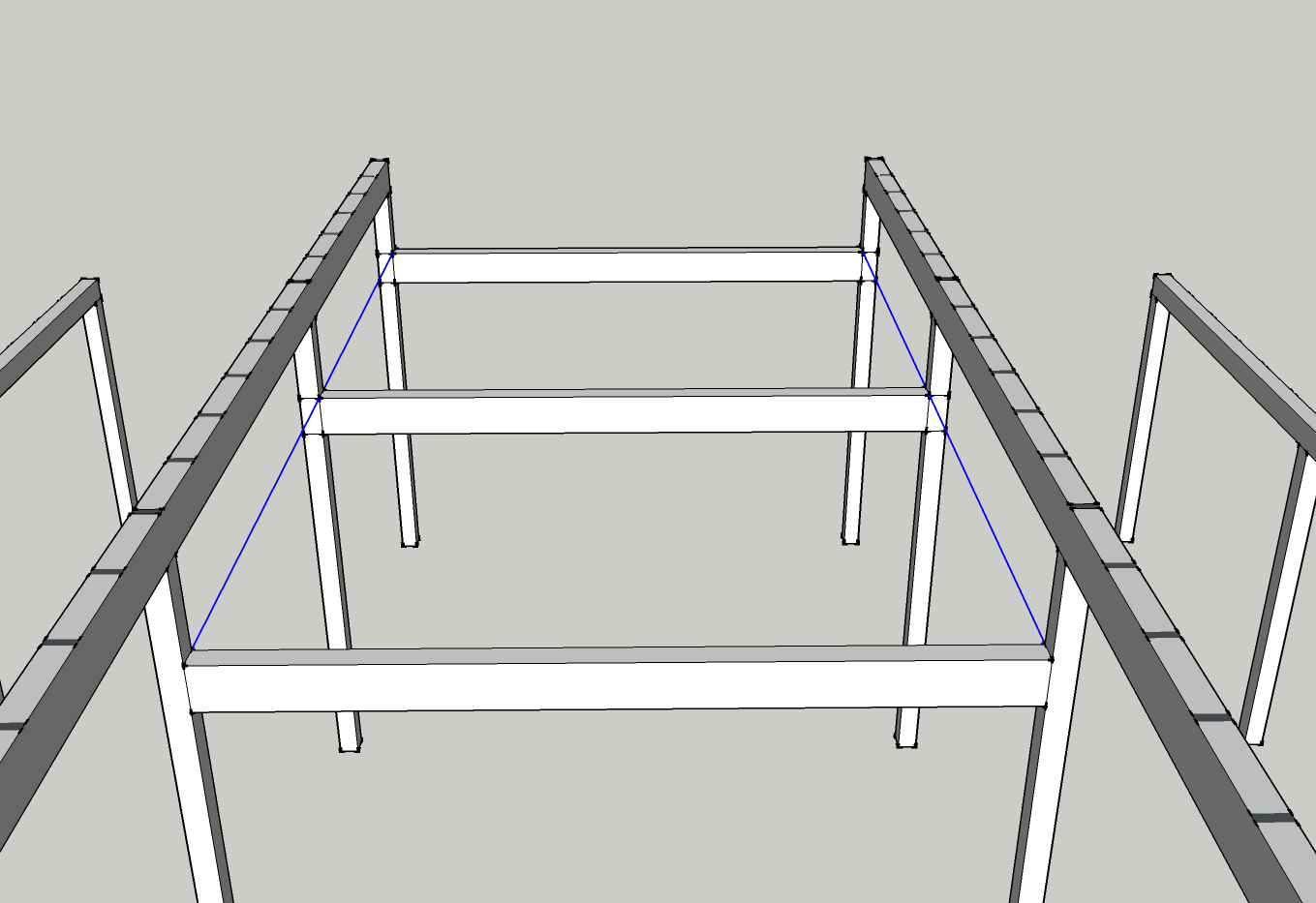

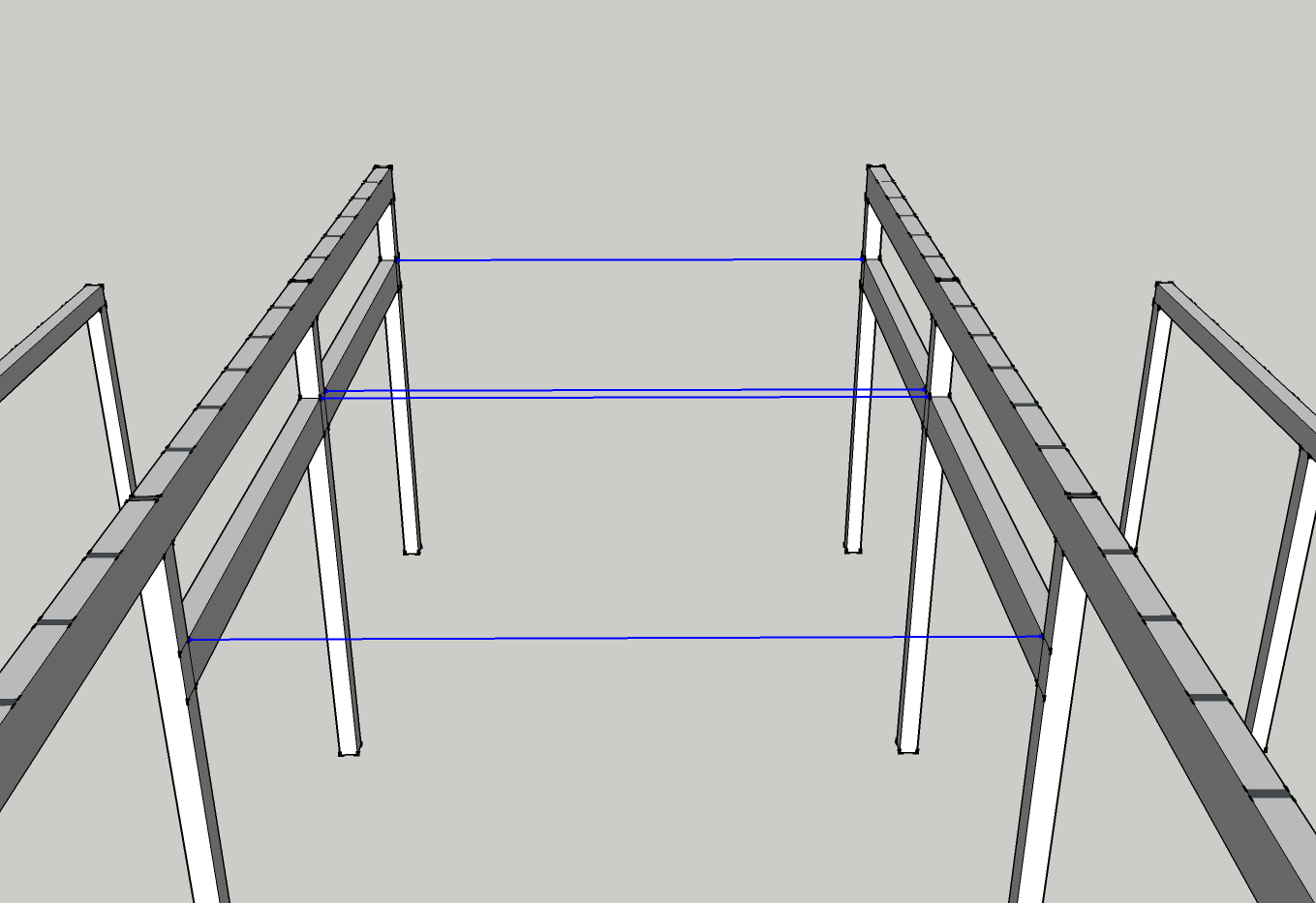

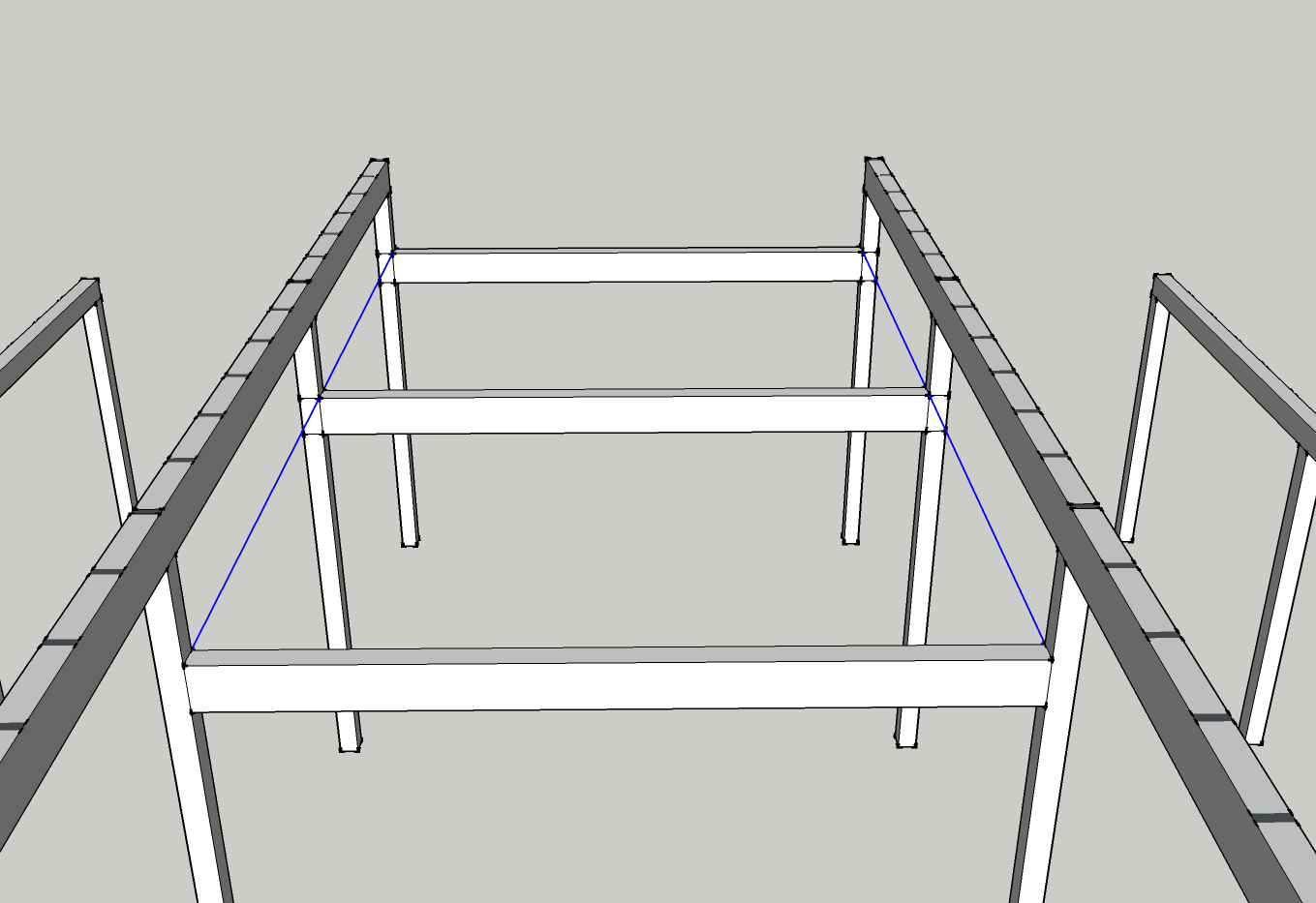

I have a couple options for "engineering" the loft floor:

1. Support beams lengthwise/North-South (12 ft) and then floor joists horizontally between/East-West (16 ft)

2. Support beams horizontal/E-W (16 ft) and floor joists lengthwise/N-S (12 ft)

Is there a clear winner between either option? See attached drawings. I'll tell you after I get some replies what my reasoning is in favoring one over the other, but I'm not a contractor.

Needs to be engineered for about 3 bales high of hay storage.

By my reckoning that equates to about 60 psi live load or 70 psi total load.

16' x 24' loft = 384 ft2

384 ft2 x 70 psi = 26,880 lbs total load max (like I'll ever put that much up there!)

Thanks.

Marcus

I have a couple options for "engineering" the loft floor:

1. Support beams lengthwise/North-South (12 ft) and then floor joists horizontally between/East-West (16 ft)

2. Support beams horizontal/E-W (16 ft) and floor joists lengthwise/N-S (12 ft)

Is there a clear winner between either option? See attached drawings. I'll tell you after I get some replies what my reasoning is in favoring one over the other, but I'm not a contractor.

Needs to be engineered for about 3 bales high of hay storage.

By my reckoning that equates to about 60 psi live load or 70 psi total load.

16' x 24' loft = 384 ft2

384 ft2 x 70 psi = 26,880 lbs total load max (like I'll ever put that much up there!)

Thanks.

Marcus