KubotaTomR

New member

- Joined

- Oct 1, 2020

- Messages

- 9

- Tractor

- Kubota BX2230

I have a Woods SGT60 rototiller made in Italy in 1998. It started to leak oil from the seals near the gear case. There are three gears for the drive unit. I was able to remove the center gear by driving bolts (14mm) thru the threaded holes in the gear. The bolts pushed against the gear case forcing the gear toward the end of the short shaft, which is part of the gear case, and off. The center gear has a bearing which actually fits on the shaft.

The top and bottom gears are trouble. The top is attached to the drive shaft; the bottom to the tiller tines shaft. Both have drive threads as the center gear, but if I drive bolts through them, I would be driving the bolts right into the bearings for shafts. I put steel plates behind the gear in an effort to protect the bearings, but they do not budge when I drive the bolts through. The top and bottom gears have three keys on each shaft. Any thoughts on how to get these gears off without destroying anything? Is there something special about these Italian made units?

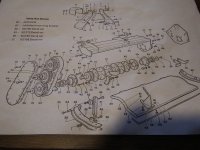

I could only find a part diagram for this tiller; not a service manual.

The gears have to come off in order to get the gear case off and get to the rest of the parts on the shaft.

My next step might be to heat the gear, but not looking forward to that.

Any thoughts would be appreciated.

I read Maletti made tillers for Woods and that is now Kverneland.

The top and bottom gears are trouble. The top is attached to the drive shaft; the bottom to the tiller tines shaft. Both have drive threads as the center gear, but if I drive bolts through them, I would be driving the bolts right into the bearings for shafts. I put steel plates behind the gear in an effort to protect the bearings, but they do not budge when I drive the bolts through. The top and bottom gears have three keys on each shaft. Any thoughts on how to get these gears off without destroying anything? Is there something special about these Italian made units?

I could only find a part diagram for this tiller; not a service manual.

The gears have to come off in order to get the gear case off and get to the rest of the parts on the shaft.

My next step might be to heat the gear, but not looking forward to that.

Any thoughts would be appreciated.

I read Maletti made tillers for Woods and that is now Kverneland.