There I was minding my own business, not doing anything wrong, when the gearbox started to shimmy, shake and then brake and not bake!

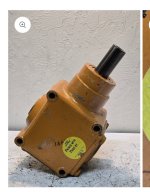

Woods 13252 gearbox replacement is what’s on the menu. Near impossible to find.

Have Google Fu’d it. Messicks etc etc.

Contacted Woods, awaiting reply same with local dealers.

It’s an oldie but a goodie.

Anybody have any suggestions from the cheap seats?

Woods 13252 gearbox replacement is what’s on the menu. Near impossible to find.

Have Google Fu’d it. Messicks etc etc.

Contacted Woods, awaiting reply same with local dealers.

It’s an oldie but a goodie.

Anybody have any suggestions from the cheap seats?