crash325

Elite Member

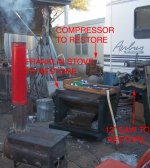

Wood stove #5 is almost completed. Built the first fire in it yesterday. First test went pretty well. A few creaks & groans at first and 1 loud bang when it got real hot. There was a little smoke coming out of one of the heat traps. Maybe a burn through hidden by flux. Plan on sealing the ends of them anyway.

This morning another real hot fire to get all the metal relaxed. Then seal the door, add finishing touches & paint.

Performance wise, it works well. When dampers are set right smoke can be seen swirling around air inlet, with just a wisp or no smoke out the pipe. When set wrong stove can get into what I call a huffing condition. That is where it flashes back. Cure for that is to shorten the damper pipe inside the stove. Burn time should be real good. Loaded with old cut off 2x4s after 2 hours of mostly hot burning it was still going strong. I shut it down and quit for the day.

Building was a bag of worms, almost nothing went right or according to plans. Tried too many new ideas and the parts count went out of site. Over 60 and it felt like over a 100. Way too much cutting, fitting & welding. Should I build another stove it will be back to simple. Stove weights around 200 pounds, fair amount of thermal mass.

#1 - Ash hole for clean out. - Not really needed, just as easy to shovel

the ashes out. Now I need to make a rake to pull them out with.

#2 - Flap type air damper door. - Back to the tried and true Guillotine type.

Hot water tanks are now only about 90 thousands thick. In the future will try to find old propane or compressor tanks.

In last picture the stove is burning. Look close and there is a wisp of smoke.

This morning another real hot fire to get all the metal relaxed. Then seal the door, add finishing touches & paint.

Performance wise, it works well. When dampers are set right smoke can be seen swirling around air inlet, with just a wisp or no smoke out the pipe. When set wrong stove can get into what I call a huffing condition. That is where it flashes back. Cure for that is to shorten the damper pipe inside the stove. Burn time should be real good. Loaded with old cut off 2x4s after 2 hours of mostly hot burning it was still going strong. I shut it down and quit for the day.

Building was a bag of worms, almost nothing went right or according to plans. Tried too many new ideas and the parts count went out of site. Over 60 and it felt like over a 100. Way too much cutting, fitting & welding. Should I build another stove it will be back to simple. Stove weights around 200 pounds, fair amount of thermal mass.

#1 - Ash hole for clean out. - Not really needed, just as easy to shovel

the ashes out. Now I need to make a rake to pull them out with.

#2 - Flap type air damper door. - Back to the tried and true Guillotine type.

Hot water tanks are now only about 90 thousands thick. In the future will try to find old propane or compressor tanks.

In last picture the stove is burning. Look close and there is a wisp of smoke.

Attachments

-

stove no5.jpg69.9 KB · Views: 897

stove no5.jpg69.9 KB · Views: 897 -

stove top.jpg78.2 KB · Views: 761

stove top.jpg78.2 KB · Views: 761 -

top straighting.jpg86.2 KB · Views: 717

top straighting.jpg86.2 KB · Views: 717 -

ash hole 5.jpg79.4 KB · Views: 768

ash hole 5.jpg79.4 KB · Views: 768 -

stove damper.jpg65 KB · Views: 1,117

stove damper.jpg65 KB · Views: 1,117 -

front 1.jpg108.7 KB · Views: 885

front 1.jpg108.7 KB · Views: 885 -

heat trap.jpg79 KB · Views: 823

heat trap.jpg79 KB · Views: 823 -

stove baffle.jpg60.1 KB · Views: 2,152

stove baffle.jpg60.1 KB · Views: 2,152 -

stove 5 damper.jpg137.6 KB · Views: 1,385

stove 5 damper.jpg137.6 KB · Views: 1,385 -

stove 5 leggs.jpg133.9 KB · Views: 868

stove 5 leggs.jpg133.9 KB · Views: 868 -

stove 5 burn 1.jpg161.7 KB · Views: 1,736

stove 5 burn 1.jpg161.7 KB · Views: 1,736