wroughtn_harv

Super Member

Boy I bet that's got the woodwork shaking./w3tcompact/icons/laugh.gif

Here's the sitchyation.

My tractor's a JCB165HF. I call her Iris cause, well, my grandma on my mama's side was called Iris.

She's a skid steer sorta like a Bobcat if someone capable of thinking out of the box had designed her.

The problem with drilling holes with a skid steer is they are designed for lifting, not pushing down.

For some time I've been thinking along the line of adding weight to the front lifting arm and then ingenuously devising a way to extend it out front compounding the weight, sorta like that Don guy did down there in God's country outside of Austin.

Man that's a lot of complicated thinking. Got myself a headache even trying to figure all the ins and outs of that configuring.

So now I've decided I'm gonna be simple.

The bottom of the tractor is protected by a solid belly pan front to back. There are two scupper kinds of pieces that run front to back on each side that are for draining debris etc.

I'm thinking about putting a couple of pieces of heavy wall rectangular tube, say three by four quarter wall along the scupper thingys.

In these will be other pieces of steel tube that slide in and out.

Here's the thought. When I need to apply down pressure on the auger I manually slide the inner tubes out to the rear. I pin these in place.

On the end of these tubes I have a method of attaching a pad.

What this does is when I apply the down pressure on the auger instead of the tractor raring up like a goosed pony and taking weight off the auger the arms out the back with the pads pick up the weight of the tractor and transfer it back to the auger.

Yup, I thought of that. Bent tubular arms are a definate for sure maybe most likely. It just so happens I have a couple of good points up high on the back of the cab to attach two other arms to angle down and back to the pads to pick up the bulk of the weight transfer.

I'm thinking I'd like this to be a simple pull tubes and pin kind of thing without any need for additional hydraulics and controls etc. I figure if the pads can be four feet off the back of the tractor and four inches or so off the ground I'll just have to be aware in tight spaces.

The pads won't be activated until they're needed when the weight transfer initiates them into place.

Here's the math part. Tractor weighs fifty four hundred pounds. It's about ten feet long. With a skid steer the bulk of the weight is around and behind the rear wheels. As I said, it's for lifting.

Now the shorter the distance from the rear of the tractor the pads are located the easier it's gonna be on everything involved. So if someone can figure out the down pressure with the pads at say two feet back versus three feet and even four feet.

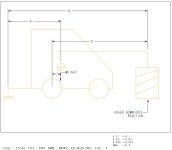

I'm not real good at this word drawing stuff. But I'm even worse at the computer drawing.

A little help will be appreciated.

Keep in mind. This modification will only be needed when I'm in serious rock, which isn't that often. It's just that when you need it bygawd you need it.

I generally know when I'm gonna be in an area where there might be rock. So this thing will be one of those deals where hopefully it'll be just a matter of minutes to set it up. With the pads four inches off the ground I'll still be plenty mobile for moving hole to hole. But if and or when I hit rock it will only be a matter of applying downforce to go from bushel baskets of grins instead of truckloads of bad words.

Here's the sitchyation.

My tractor's a JCB165HF. I call her Iris cause, well, my grandma on my mama's side was called Iris.

She's a skid steer sorta like a Bobcat if someone capable of thinking out of the box had designed her.

The problem with drilling holes with a skid steer is they are designed for lifting, not pushing down.

For some time I've been thinking along the line of adding weight to the front lifting arm and then ingenuously devising a way to extend it out front compounding the weight, sorta like that Don guy did down there in God's country outside of Austin.

Man that's a lot of complicated thinking. Got myself a headache even trying to figure all the ins and outs of that configuring.

So now I've decided I'm gonna be simple.

The bottom of the tractor is protected by a solid belly pan front to back. There are two scupper kinds of pieces that run front to back on each side that are for draining debris etc.

I'm thinking about putting a couple of pieces of heavy wall rectangular tube, say three by four quarter wall along the scupper thingys.

In these will be other pieces of steel tube that slide in and out.

Here's the thought. When I need to apply down pressure on the auger I manually slide the inner tubes out to the rear. I pin these in place.

On the end of these tubes I have a method of attaching a pad.

What this does is when I apply the down pressure on the auger instead of the tractor raring up like a goosed pony and taking weight off the auger the arms out the back with the pads pick up the weight of the tractor and transfer it back to the auger.

Yup, I thought of that. Bent tubular arms are a definate for sure maybe most likely. It just so happens I have a couple of good points up high on the back of the cab to attach two other arms to angle down and back to the pads to pick up the bulk of the weight transfer.

I'm thinking I'd like this to be a simple pull tubes and pin kind of thing without any need for additional hydraulics and controls etc. I figure if the pads can be four feet off the back of the tractor and four inches or so off the ground I'll just have to be aware in tight spaces.

The pads won't be activated until they're needed when the weight transfer initiates them into place.

Here's the math part. Tractor weighs fifty four hundred pounds. It's about ten feet long. With a skid steer the bulk of the weight is around and behind the rear wheels. As I said, it's for lifting.

Now the shorter the distance from the rear of the tractor the pads are located the easier it's gonna be on everything involved. So if someone can figure out the down pressure with the pads at say two feet back versus three feet and even four feet.

I'm not real good at this word drawing stuff. But I'm even worse at the computer drawing.

A little help will be appreciated.

Keep in mind. This modification will only be needed when I'm in serious rock, which isn't that often. It's just that when you need it bygawd you need it.

I generally know when I'm gonna be in an area where there might be rock. So this thing will be one of those deals where hopefully it'll be just a matter of minutes to set it up. With the pads four inches off the ground I'll still be plenty mobile for moving hole to hole. But if and or when I hit rock it will only be a matter of applying downforce to go from bushel baskets of grins instead of truckloads of bad words.