rootytoot

Member

- Joined

- Jul 16, 2008

- Messages

- 49

- Location

- Western Oregon

- Tractor

- Ford/NH Model 1920, Allis Chalmers Model G

Hi, I've decided to finally get started on restoring the Allis-Chalmers Model G that I bought a few years back. There's enough rust on it that I plan to take it apart down to individual bits, and have it sandblasted to remove rust and the remnants of the original paint. After that... take it to a specialist for painting (after reading FarmWithJunk's long thread on painting I think it is best to not start up a new hobby as a painter).

I was thinking that it would make sense to take it to a powder coating business for all of the wear areas: pedals, bars, master tool lift, etc. And then take the larger, non-wear pieces like the transmission and wheels to an auto body type painter for standard liquid spray-on paint. I would have the powder coated pieces done first, and then let the liquid paint guy match the powder color.

So, I'm looking for advice from folks who have been there... what sort of questions should I be asking the painting guys? And what sort of answers are 'good' answers? I've read in some threads that sandblasting won't get 100% of the rust off, and that I should think about

- phosphoric acid treatment to convert the rest of the rust?

- zinc-rich primer after that?

- urethane paint? Imron? One coat? Two coats?

Should I be looking for the same chemical / primer prep steps on the powder coat parts?

What about springs? The G has mechanical springs on it in various places. Should those be stretched out somehow to separate the coils, and then painted with liquid paint? Is there a particular kind of paint that can allow movement of the coils without cracking?

What about integral threaded fasteners (ones that are part of another, larger part)? Have those sandblasted, primed, painted? Or just sandblast, mask off the threads, coat with oil for corrosion protection? I'm thinking it would be a good idea to just replace all the standard bolts with good quality galvanized nuts and bolts, although the original A-C bolts appear to have all been painted.

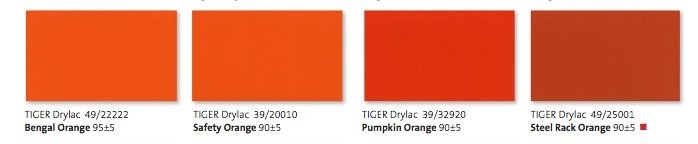

Finally, color... there are a couple of orange colors in the Tiger/Drylac powder coating catalog: Bengal Orange, Safety Orange, Pumpkin Orange, and Steel Rack Orange. Bengal and Safety Orange look pretty similar as a bright orange, Pumpkin Orange has a reddish tint, and Steel Rack Orange has a darker look. I'm thinking that Steel Rack Orange has the most original look, but I'd be interested to hear opinions.

OK, that's all I can think of tonight. Thanks for your advice,

Kurt

I was thinking that it would make sense to take it to a powder coating business for all of the wear areas: pedals, bars, master tool lift, etc. And then take the larger, non-wear pieces like the transmission and wheels to an auto body type painter for standard liquid spray-on paint. I would have the powder coated pieces done first, and then let the liquid paint guy match the powder color.

So, I'm looking for advice from folks who have been there... what sort of questions should I be asking the painting guys? And what sort of answers are 'good' answers? I've read in some threads that sandblasting won't get 100% of the rust off, and that I should think about

- phosphoric acid treatment to convert the rest of the rust?

- zinc-rich primer after that?

- urethane paint? Imron? One coat? Two coats?

Should I be looking for the same chemical / primer prep steps on the powder coat parts?

What about springs? The G has mechanical springs on it in various places. Should those be stretched out somehow to separate the coils, and then painted with liquid paint? Is there a particular kind of paint that can allow movement of the coils without cracking?

What about integral threaded fasteners (ones that are part of another, larger part)? Have those sandblasted, primed, painted? Or just sandblast, mask off the threads, coat with oil for corrosion protection? I'm thinking it would be a good idea to just replace all the standard bolts with good quality galvanized nuts and bolts, although the original A-C bolts appear to have all been painted.

Finally, color... there are a couple of orange colors in the Tiger/Drylac powder coating catalog: Bengal Orange, Safety Orange, Pumpkin Orange, and Steel Rack Orange. Bengal and Safety Orange look pretty similar as a bright orange, Pumpkin Orange has a reddish tint, and Steel Rack Orange has a darker look. I'm thinking that Steel Rack Orange has the most original look, but I'd be interested to hear opinions.

OK, that's all I can think of tonight. Thanks for your advice,

Kurt