DaveOmak

Platinum Member

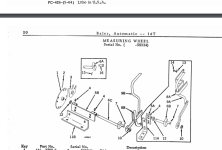

I've noticed, that on occasion, I can't manually initiate the knotting sequence... There is some sort of safety mechanism that won't allow that sequence UNLESS there has been approximately +/- 21 cycles of the plunger and the "safety bar"(#1) is lowered into the "go ahead and tie the bale" position... that safety bar is connected to the rotating "star" that measures the bale length... At the proper bale length the safety bar(#1) is in position to initiate the knot, BUT there is a second "guard"(#2) that won't move to clear a path until approx 21 plunger cycles have happened....

What or where counts the plunger cycles that allows all this to happen ???

After a bale is tied, #1 is on top of #2... approx. 21 plunger cycles, #1 moves to it's current location ... With the star rotation, #4 pushes on #3 and initiates a knotting cycle...

What I don't understand is... the rotation of #2, how it is moved and what initiates the movement after ~21 plunger cycles... I can't see or find anything that moves during the 21 plunger cycles..

I am amazed someone figured out how to build this knotter and I would like to have met him..

...

... ...

...

What or where counts the plunger cycles that allows all this to happen ???

After a bale is tied, #1 is on top of #2... approx. 21 plunger cycles, #1 moves to it's current location ... With the star rotation, #4 pushes on #3 and initiates a knotting cycle...

What I don't understand is... the rotation of #2, how it is moved and what initiates the movement after ~21 plunger cycles... I can't see or find anything that moves during the 21 plunger cycles..

I am amazed someone figured out how to build this knotter and I would like to have met him..

...

... ...

...