cockeyedMFer

Gold Member

- Joined

- Jul 25, 2011

- Messages

- 264

- Tractor

- 1959 MF 35 deluxe, gas

Sorry if this is the wrong forum, but I'll try here first.

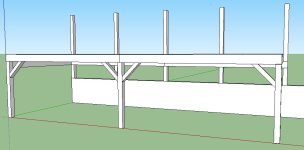

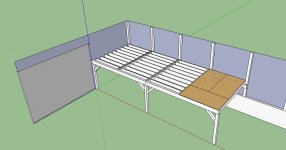

Has anyone worked with 3x10 lumber before? I lucked into some beautiful pine 3x10x16 beams, #1 s4s untreated. I'd like to use them as headers on my 32x12' storage loft project.

Problem is that span tables no longer list 3x10, but years ago this size was common in homes and barns.

I was thinking of sistering 2 3x10's to span 16' centers, supported by 6x6 posts. Alternately it could be done on 12' centers but I'd prefer the longest clear span possible.

What do you guys think?

Has anyone worked with 3x10 lumber before? I lucked into some beautiful pine 3x10x16 beams, #1 s4s untreated. I'd like to use them as headers on my 32x12' storage loft project.

Problem is that span tables no longer list 3x10, but years ago this size was common in homes and barns.

I was thinking of sistering 2 3x10's to span 16' centers, supported by 6x6 posts. Alternately it could be done on 12' centers but I'd prefer the longest clear span possible.

What do you guys think?