</font><font color="blue" class="small">( I understand that someone at Daedong USA had read this post and contacted the Australia Distributor, Amazing as this may seem one must be impressed with Daedong and there commitment to their customers. )</font>

There are several people at Daedong USA who keep up with this forum, and who know what the pulse of the buyers is. I think it's great that someone took the time to investigate and get involved.

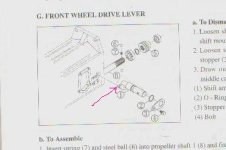

I didn't want to sound scolding when you originally posted that you shift on the go, but if you really thing about how the mechanism engages, you'd realize the trying to mesh the gears while moving can only work with synchronizers. Cast steel shatters, not bends by its very nature. A good reason for changing that. If you were to take a sledge hammer to a cast bathtub for instance, it would simply shatter with every blow. When it first breaks, one would see a shinier area at the break. As for the lack of a broken piece, I don't know, but it must have been able to get out somehow?

Glad to hear you're back in operation. I'm even more careful about not engaging while moving than before this happened to you. Thanks for posting. John