PeteN

Silver Member

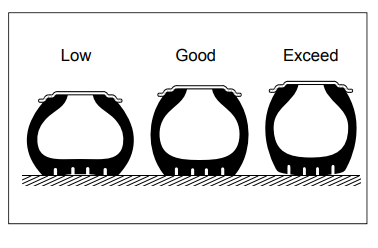

I've looked through the owner's manual for my MT357HC to find nominal tire pressures for the R4's I have on this tractor. Nothing listed for the size of R4's installed. About the only recommendation I found in the manual was a drawing showing the tread to be flat with the ground and not cupped in either direction.

The max tire pressure listed on the tires is 40psi. I'm not using the loader right now so I'm going to play around with tire pressures to see if there is any improvement in traction or ride. Any recommendations? Front is a 12-16.5 with a 17.5-24 rear.

The max tire pressure listed on the tires is 40psi. I'm not using the loader right now so I'm going to play around with tire pressures to see if there is any improvement in traction or ride. Any recommendations? Front is a 12-16.5 with a 17.5-24 rear.