James Eric

Silver Member

- Joined

- Dec 28, 2009

- Messages

- 103

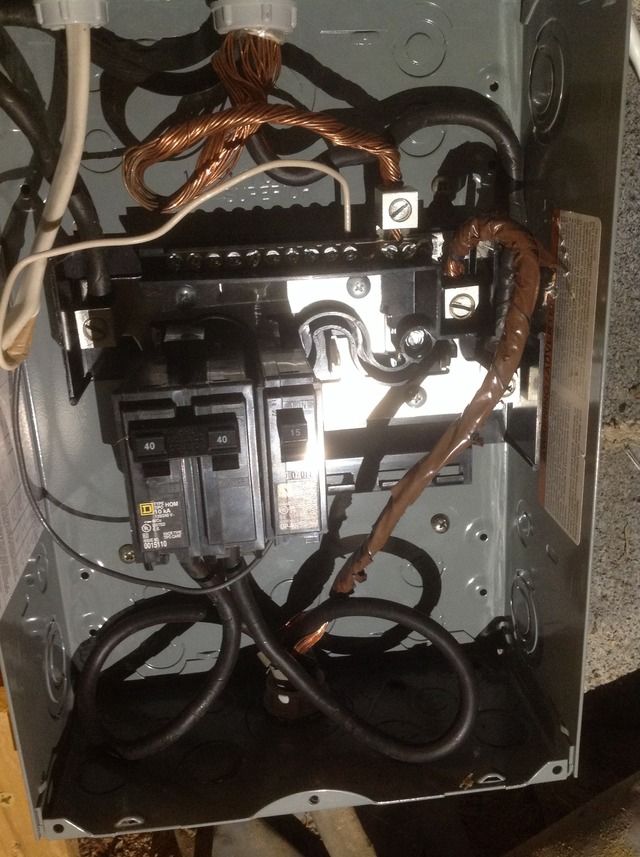

My flux core welder has a jerky wire feed problem but a friend with the same make and model does not have the same problem. Yesterday we tried his welder at my shop and it had the same problem. When he returned home his welder acted normal again. We think the problem is the electrical service in my barn. My barn is fed by 3 wire service. It has a disconnect where it enters the barn and a 100amp breaker panel in the shop area that services the outlets, lights, welder, and compressor. I do not perform electrical service but I need to identify the problem so that I can hire someone to fix it right.

Any ideas on what would cause this situation?

Thanks,

James

Any ideas on what would cause this situation?

Thanks,

James