slvr98svt

New member

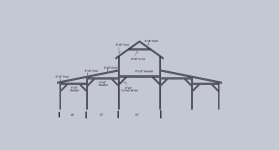

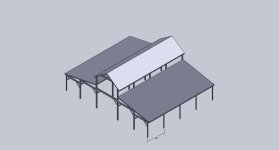

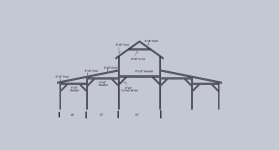

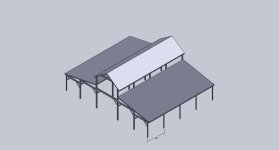

Hey guys I have been gathering some info from resources online and trying to get an idea of what I want for a monitor style barn. I drew up a quick diagram with sizes that I am looking for help on. The 10' width will be open "lean-to's", with the 12' sections being stalls on one side and storage on the other and then obviously a 16' open center.

I have looked up a couple of the online calculators and tried to use them to size the beams and posts but, I are dumb when it comes to the names and trying to decide if its actually what I am calculating. So with that, I am looking at storing hay in the loft but want to make sure it is safe to do so. This will all be rough cut, dried lumber, cut to actual size. There will be 5 sections totaling a length of 48'. So with 8x8 posts for the aisle, and 8x10 "headers" spanning the 16' with corner braces. If I use 2x10's running the "length" of the building on 12 or 16" center's (connecting the 8x10 together) what would floor load bearing being?

Thanks guys, just napkin sketches right now.

-Matt

I have looked up a couple of the online calculators and tried to use them to size the beams and posts but, I are dumb when it comes to the names and trying to decide if its actually what I am calculating. So with that, I am looking at storing hay in the loft but want to make sure it is safe to do so. This will all be rough cut, dried lumber, cut to actual size. There will be 5 sections totaling a length of 48'. So with 8x8 posts for the aisle, and 8x10 "headers" spanning the 16' with corner braces. If I use 2x10's running the "length" of the building on 12 or 16" center's (connecting the 8x10 together) what would floor load bearing being?

Thanks guys, just napkin sketches right now.

-Matt