freefour

New member

I want to build a small three sided equipment shed to house my implements. I helped a friend tear down a metal shed last year that got partly damaged (built around 1980). He gave me all the metal and decent 2x6 lumber from it. I been checking with my local coop and finally got some utility poles. I have enough room for a 16'x 40' shed (open on 40' side). I am trying to do this as economical as possible so I am going with a mono slope roof. I got the poles already set on 10' centers, 8 feet high in the back and 11 feet in the front. I live in southern Illinois and we do not get much snow. However, in the 10 years I have lived here we have had a foot once or twice.

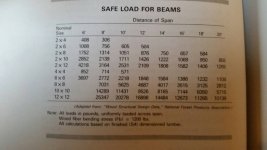

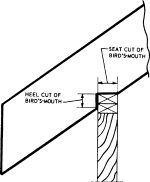

What I need some advice on is the roof. My thoughts is to go with 2x10x10' across the front and back of the building (girders?) then stand 2x6x16' rafters every four foot on top of them front to back. I was then going to lay down 2x4x12' purlins every two feet from front to back (overlapping them) from side to side for the metal to lay on. Will that be strong enough? Do I need the girders on the backsides of the poles too?

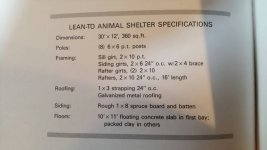

I have one friend that say he wouldn't go less than every two feet for rafters. That seems like over kill to me but I am not sure. Another buddy says I should build it like his lean to and skip the girders and bolt 2x10x16' from front to back directly to my poles then stand up the 2x4 purlins on top of that. He said he was told that would hold much more weight. Ten feet seem like a long span for a 2x4 but that is how his is built. It had no problems with those foot snows we had.

Anyway, my reason for using the 2x6x16' is because I already have 10 of them. I can use them elsewhere if it isn't strong enough for rafters.

Any thoughts are appreciated.

What I need some advice on is the roof. My thoughts is to go with 2x10x10' across the front and back of the building (girders?) then stand 2x6x16' rafters every four foot on top of them front to back. I was then going to lay down 2x4x12' purlins every two feet from front to back (overlapping them) from side to side for the metal to lay on. Will that be strong enough? Do I need the girders on the backsides of the poles too?

I have one friend that say he wouldn't go less than every two feet for rafters. That seems like over kill to me but I am not sure. Another buddy says I should build it like his lean to and skip the girders and bolt 2x10x16' from front to back directly to my poles then stand up the 2x4 purlins on top of that. He said he was told that would hold much more weight. Ten feet seem like a long span for a 2x4 but that is how his is built. It had no problems with those foot snows we had.

Anyway, my reason for using the 2x6x16' is because I already have 10 of them. I can use them elsewhere if it isn't strong enough for rafters.

Any thoughts are appreciated.