Guy, congrats on the decision to build a firewood processor. We finished ours up last fall and it ended up working well for us (after working out a few bugs) It's real time and back saver.

A couple of question for you on the design plans & requirements.

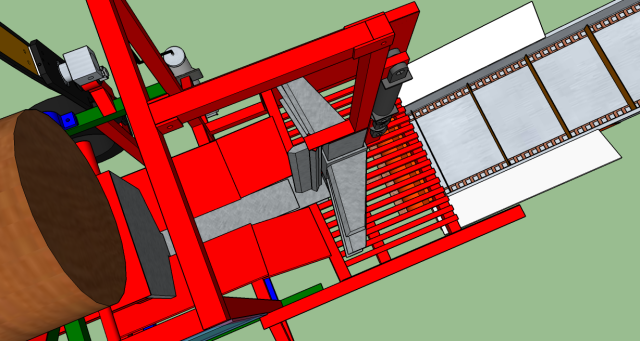

-Is the saw going to be hydraulic or are you planning on using a regular chainsaw on a pivot? If hydraulic I am worried about your engine and pump being able to run a saw. Definitely don't go for .404 chain. Stick to .375

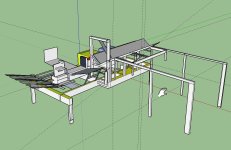

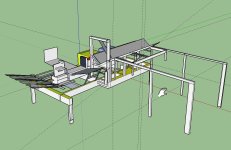

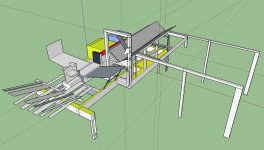

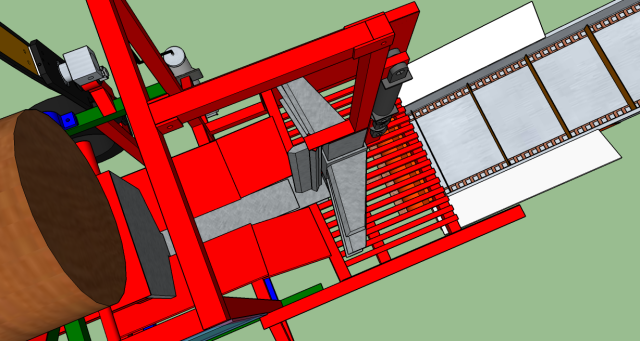

-What are you planning on doing with the wood after it is split? Efficient evacuation of split wood is one of the biggest issues. You will build up a pile that backs up into the wedge in no time. I see a ramp after the splitter. I don't see that fairing too well.

KiotiKen tried and it did not work. I don't think that using the ram to push the split logs with more split logs really works. Inevitably you need to get at the log you just split all too often. You will need to lift it out to split it again, get in there to clear jams, pound logs out backwards that just won't split.

-Where are you planning on putting the controls? I see you needing to tend to things on both sides of the machine quite often. OK if you are planning on running with 2 people but cumbersome and time consuming with one. The loading of logs into the trough from the infeed rack, winching them through, and dealing with the saw are on one side and the splitter is on the other. I like offset designs for their ability to keep things at a lower height but inline keeps things closer for one operator. Its a tradeoff.

-It may be in your mental plans but not in the drawing, but, I don't see a log clamp behind the saw. You will need one otherwise the log will move during cutting and the chain will bind.

-We planned our processor to be capable of running 24" dia. logs. That will never happen. If the log were venere grade, straight as an arrow, beautiful straight grain, possibly, but I doubt it. 14 or so is the most we've dared to run on it. If you run into a medium sized knot in there it will bind all up in the wedge and it is no fun at all. You just lost 30 to 45 minutes getting the thing back out. So that being said, having the initial plan for the processor to be able to run 24" has helped tremendously because almost no logs are straight. The curves, kinks, and bends in the log will take away from the actual capacity. Hard to explain without seeing it but if you have a 12" log with even a slight bend in it, it could be outside of the reach of the clamp or the saw bar might not cut through the far side. So I say plan the clamp and bar for larger than what you will actually cut. You won't be able to process a 16" log with a 16" or even a 20" bar.

-I like the idea of the log lift on there to split things that were not cut on the processor. That would be real handy! Wish we had that capability sometimes.

OK, on to the questions that you had asked:

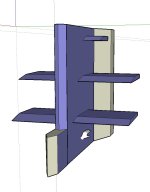

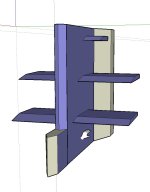

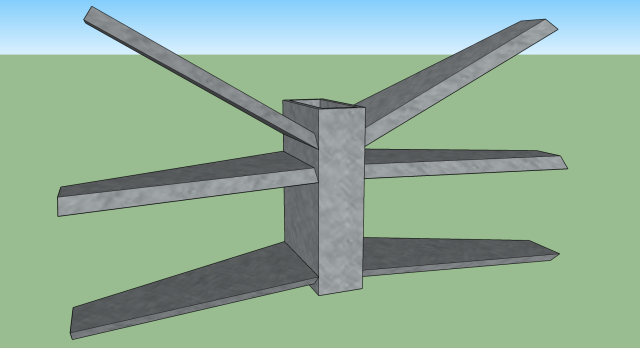

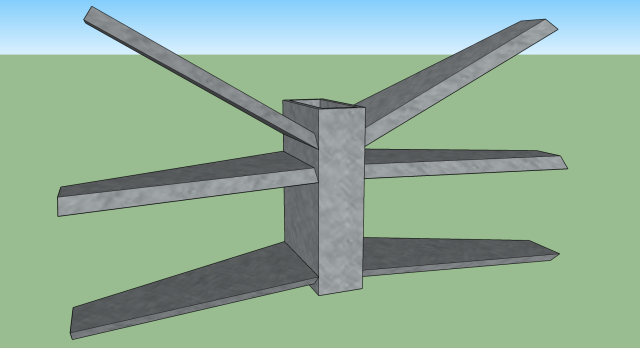

-I see 2 wedge designs. I don't see either working as is. On both of them I would loose the top little wedge that makes it an 8-way. I think it's just too much for a 13hp to handle.

The wedge that is rendered needs to have the bevels of the bottom two wings to go in opposite directions. The split log will jam into the upper wedge and stop dead in its tracks. The bottom wedge needs to send the split down and the top one needs to send it up. Plus you need to raise the top of back of the top wedge to allow for some relief as the split runs through.

Discussed a bit here in this thread. As far as the second wedge design it could work without the top wedge. That would cause everythig to bind since the splits form the vee will want to ride up and get stopped at the top wedge. Here is our multi-wedge design

With any type of progressive multi wedge (full length vertical split is done first and then it proceeds to the multi wedge) I think you want the tips of the multi wedge to engage before the center. It helps to prevent the log from just opening up and not splitting once it hits the multi wedge. You will still have issues with it on some logs but it does a pretty good job of keeping it to a minimum.

That and I don't think you need to have the step in the main vertical wedge at the bottom. Just make it straight up and down. If you have a log that requires the initial vertical split to be progressive you will never get it through the multi wedge. I guess this statement is null and void if you are planning on having the multi wedge be removable. If you'r planning on being able to split things just in half you could leave it in there.

I look forward to seeing the progress.