dsails380

New member

Like others, I'm tired of manually reversing the auger to get it unstuck. The 3 pt hitch just can't pull it out of the limestone and shale. I'd like to convert to a reversible hydraulic PHD system. The ETA digger and augers barely have 16 hrs on them, so I'm reluctant to part with them.

Tractor information: M-F GC 2410 TLB. Open center hydraulics. 4.3 GPM at rear remote. 1900 psi relief valve setting. 18.7 hp @ 555 rpm rear PTO. There are 3 hoses at the rear remote pump supply, pump return, and direct return to sump.

1.) Determine which hydraulic motor to use for low speed, high torque. 18.7 hp rear PTO =177 ft-lb torque, or 2123 in-lb torque. Surplus Center calculator indicates at 1900 psi system pressure, and a hydraulic motor displacement of 7.2 in3, maximum hydraulic motor torque will be 2178 in-lbs. With flow of 4.3 GPM and 7.2 in3 displacement, max motor speed will be 138 RPM. Dynamic BMPH125H2KP (Surplus Center) looks like the perfect combination of torque and speed, and is reversible. Am I missing anything here? Should I be looking at another, more suitable motor?

2.) Determine which Spool Valve to use. I've selected a 1 spool, 8 gpm, Prince MB11B5C1 (Surplus Center) that comes set up for open center hydraulics and bi-directional flow, for that all important reverse auger rotation. The integral relief valve comes preset at 2000 psi. Will there be a problem with overpressure of the components from this valve back to the tractor pump? Or will the tractor 1900 psi relief open first? Would a hydraulics expert select this valve for this application, or is there one better suited?

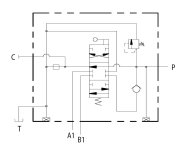

3.) How to plumb the system hydraulics? Looking at the Prince MB11B5C1 schematic, I can see that I connect the tractor pump supply hose to port "P"? I would not install the high pressure carryover plug because I want the open center hydraulics to work, and I don't need power beyond. I also see that I would connect the tractor pump return line to port "C"? Ports A1 and B1 would be connected to the Dynamic hydraulic motor ports. Now the tough question Should I connect the tractor direct return to sump hose to port "T"? I don't know enough about tractor hydraulics, so I'm again looking for an expert's opinion before I go off and do something stupid and regrettable.

Tractor information: M-F GC 2410 TLB. Open center hydraulics. 4.3 GPM at rear remote. 1900 psi relief valve setting. 18.7 hp @ 555 rpm rear PTO. There are 3 hoses at the rear remote pump supply, pump return, and direct return to sump.

1.) Determine which hydraulic motor to use for low speed, high torque. 18.7 hp rear PTO =177 ft-lb torque, or 2123 in-lb torque. Surplus Center calculator indicates at 1900 psi system pressure, and a hydraulic motor displacement of 7.2 in3, maximum hydraulic motor torque will be 2178 in-lbs. With flow of 4.3 GPM and 7.2 in3 displacement, max motor speed will be 138 RPM. Dynamic BMPH125H2KP (Surplus Center) looks like the perfect combination of torque and speed, and is reversible. Am I missing anything here? Should I be looking at another, more suitable motor?

2.) Determine which Spool Valve to use. I've selected a 1 spool, 8 gpm, Prince MB11B5C1 (Surplus Center) that comes set up for open center hydraulics and bi-directional flow, for that all important reverse auger rotation. The integral relief valve comes preset at 2000 psi. Will there be a problem with overpressure of the components from this valve back to the tractor pump? Or will the tractor 1900 psi relief open first? Would a hydraulics expert select this valve for this application, or is there one better suited?

3.) How to plumb the system hydraulics? Looking at the Prince MB11B5C1 schematic, I can see that I connect the tractor pump supply hose to port "P"? I would not install the high pressure carryover plug because I want the open center hydraulics to work, and I don't need power beyond. I also see that I would connect the tractor pump return line to port "C"? Ports A1 and B1 would be connected to the Dynamic hydraulic motor ports. Now the tough question Should I connect the tractor direct return to sump hose to port "T"? I don't know enough about tractor hydraulics, so I'm again looking for an expert's opinion before I go off and do something stupid and regrettable.